What strategies can be used to reduce occurrence risk in an FMEA?

“Luck is not chance, it’s toil; fortune’s expensive smile is earned.”

Emily Dickinson

The Oxford English dictionary defines “occurrence” as “the fact or frequency of something happening.”

Reference the article Understanding FMEA Occurrence Risk – Part 1 which discusses how Occurrence is defined and applied in FMEA.

What are “action strategies to reduce occurrence risk”?

FMEA teams can use a multitude of proven strategies to address risk associated with high occurrence. The following are two of these strategies. A full list of strategies is covered in chapter 7 of the book Effective FMEAs.

Change the design to eliminate the failure mode or cause

It is possible to eliminate the failure mode or cause by changing the design of the product or the process. In FMEA language, eliminating the failure mode or cause will reduce the likelihood of occurrence to the lowest possible level.

Example: A robot arm uses a hydraulic lifting mechanism prone to “oil leaks.” The FMEA team recommends an electronic robot arm using solenoids and motors. The failure mode “oil leak” is no longer possible. Of course, the new electronic system will have its own set of failure modes requiring consideration.

Use a factor-of-safety

One of the most effective action strategies to prevent failures is to design in a factor-of-safety. For structural applications, this is the ratio of the maximum stress that a structural part or other piece of material can withstand to the maximum stress it is anticipated to experience in the use for which it is designed. Essentially, how much stronger the system is than it usually needs to be for an intended load. The greater the factor-of-safety, the lower the likelihood of structural failure. In FMEA language, increasing the factor-of-safety reduces the frequency of the cause of the failure mode.

Historical example: Designed and built in the 1870’s the Brooklyn Bridge was widely acclaimed to be an engineering marvel. The suspension bridge structure used four large wire ropes, each rope containing 5,434 wires, each wire more than 3,500 miles long. The span of the suspension bridge was 50% longer than any previous suspension bridge and the application of steel cables in suspension bridges had never been tried previously. “The cables had been designed to have a margin of safety of six, that is, they were six times as strong as they had to be.” This factor of safety proved to be more than adequate to address manufacturing and supplier variables.

Many companies use safety factor guidelines, ranging from four or higher, to as little as 1.1. Typically, the higher the severity risk, the higher the factor-of-safety, as modified by weight, cost, and other factors.

Multiple strategies to reduce risk

As discussed in last month’s FMEA corner, in most cases reduction of a high-risk issue from an FMEA requires the use of multiple tasks. These are recorded in the Recommended Actions column.

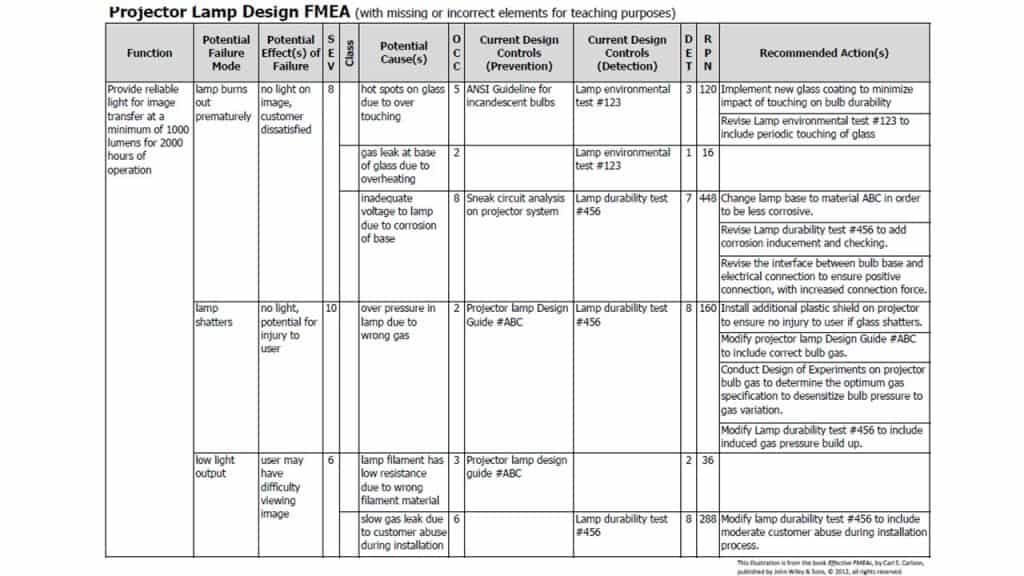

Below is an example of the use of Recommended Actions to reduce occurrence risk, as well as risk from severity and detection. It is an excerpt from a fictional Design FMEA on a projector lamp.

In this example, the FMEA team believes actions “Conduct design of experiments on projector bulb gas to determine the optimum gas specification to desensitize bulb pressure to gas variation” and “Modify projector lamp design guide to include correct bulb gas” can reduce occurrence from 4 to 2.

Note the multiple actions to address this high-severity, high-RPN issue.

FMEA Tip

If severity is 9 or 10, the team must first attempt to lower the severity ranking, such as by design change. If lowering the severity ranking is not possible or feasible, the FMEA team must confirm and verify that the occurrence and detection rankings are as low as possible (preferably 1), or must take all action necessary to achieve lowest possible occurrence and detection rankings, and then obtain management’s concurrence and support before determining that no further action is required.

Both management and the FMEA team must agree that everything possible has been done to prevent safety problems within the design life of the product or during the manufacturing process.

Problem

Which of the following are action strategies to reduce the occurrence risk? (Select all that apply)

1. Make the design fault tolerant.

2. Introduce redundancy to the design.

3. Reduce stress-strength interference.

4. Increase the design margin.

Solution

1. Make the design fault tolerant. (False. This will reduce the severity.)

2. Introduce redundancy to the design. (True. Depending on the system con?guration, it is possible to reduce the occurrence of system failure with redundant design.)

3. Reduce stress-strength interference. (True)

4. Increase the design margin. (True)

Readers Question

With regard to System FMEAs, I would expect these to be done early in a project, and at a high level in the system’s hierarchy, meaning that the design elements being analyzed are going to be the main sub-systems and assemblies that will make up the product. Scoring the Severity seems straight forward, but scoring the Occurrence and the Detection seems a bit more problematic at the System FMEA level because one may not have any useful information about those metrics.

Do you find that you can apply the usual scoring scales for O and D at the system level, or do you handle these metrics in some other way for the System FMEA?

Answer to Reader’s Question

It is often challenging to assess occurrence and detection for system FMEAs, as they occur early in the product development process, and objective data may or may not yet be available. There are ways to help with this assessment. First is good preparation, which includes having objective field-failure data on similar systems. It’s not perfect, as system configurations change, but it is helpful input to the discussion. Second is having the right team of subject matter experts in the room. They can be asked subjectively their input to the likelihood of occurrence of the failure mode / cause. Third is having representation from test on the team. This helps with the detection assessment, as to how well the currently planned testing or analysis methods can detect the failure mode / cause.

I do use the scales for O and D on system FMEAs. I hope that those tips are helpful.

Next Article

FMEA procedure includes assessing three types of risk: severity, occurrence, and detection. FMEA teams should attempt to reduce all three types of risk. In the next article, action strategies to reduce detection risk are discussed.

Leave a Reply