There is a direct connection between the microstructure health of your equipment parts and your operational and business success

There are key concepts and practices that an organization needs to use if they want optimal asset health from their plant and equipment. The greatest successes come when operating and safety risks are eliminated at their root causes. The Plant Wellness Way EAM methodology focuses on getting lasting asset health so world class operating performance is normal in your company day-after-day. Its processes and analysis tools create a system-of-reliability that gets exceptional asset health and delivers the greatest ROI from each operating asset throughout its service life.

Risk is the total losses suffered when any asset’s components may fail. The causes of failure are the environmental and operating stresses that affect a component’s microstructure. This means that world class reliability is the effective, complete remove of the causes of failure, also known as risks, from your operations.

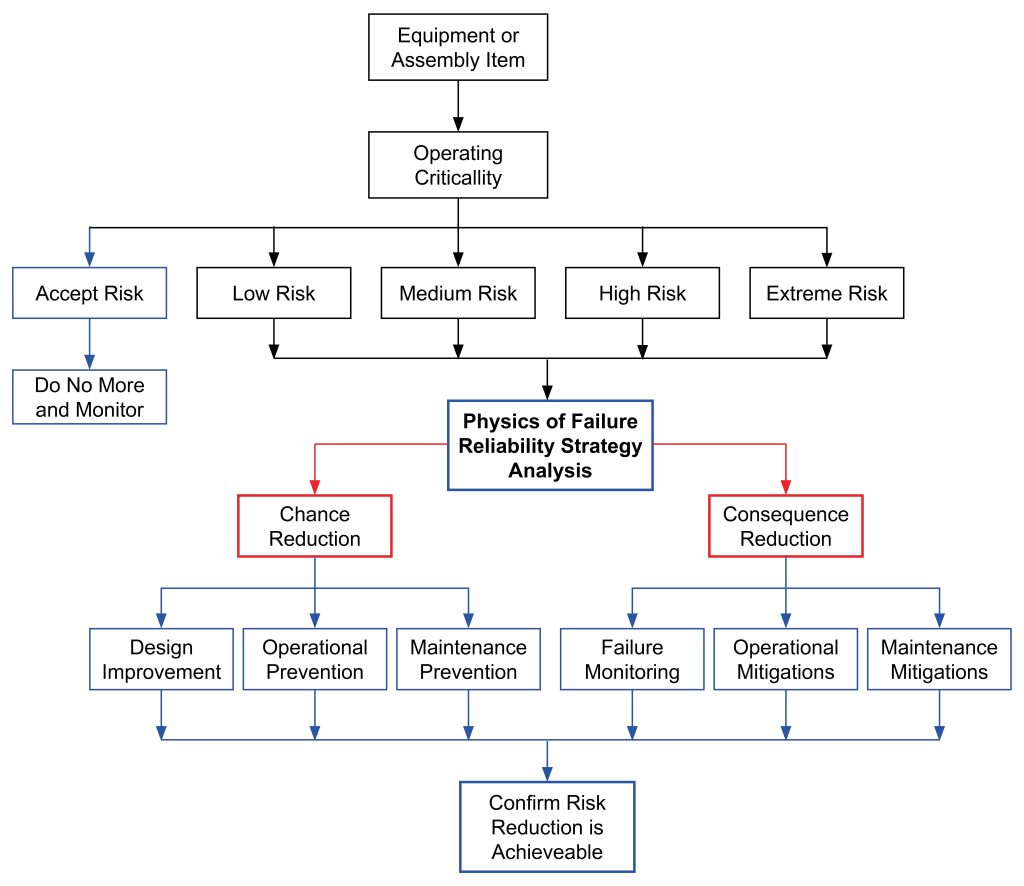

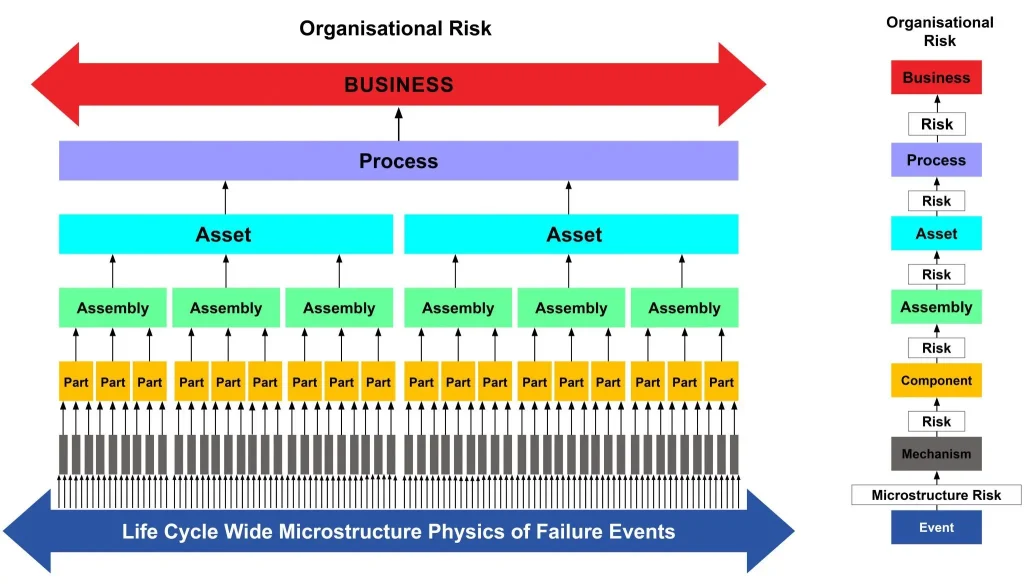

Figure 1 contains all you need to know in order to bring any operation world class reliability and improved operating profits. It shows the direct connections between the causes of business and operational risks and the reliability of your assets. When you make your assets reliable, and develop systems that support their component health, they will take your company and operations to the heights of operating success and profits.

Source: Thanks to Paul Price, a UK condition monitoring consultant, for use of this concept.

Risk Hierarchy

Every asset failure can be traced back to what was done to its components’ during their lifetime. As shown in Figure 1, there are dependency links between the initial Physics of Failure mechanisms and an organization’s performance. These links run up the hierarchy of risk, with each level relying on multiple links from below. This means that organizations can have countless causes of failure (risks) in their systems and yet still operate and be somewhat profitable. However, the state of health at each level of the hierarchy adds risk and can become a larger problem for the levels above it.

Ultimately, the reliability of every physical asset and the subsequent risks they bring to a business depends on how well you eliminate and prevent the causes of Physics of Failure mechanisms throughout its parts’ life cycles.

Common standard maintenance strategies look only at assets and assembly levels of the dependency hierarchy. As a result, failures are never, truly, prevented. The causes of failure are allowed to continue to affect the microstructure of the component until the damage is so server that is can be detected by the behavior of the asset. If failure mechanisms are present in equipment, they will generate the risk of failure.

Physics of Failure events are the operating stresses and local environment affecting a component’s microstructure. Thing such as healthy lubricant, correct lubricant film thickness, proper interference fit between mating parts, trueness of component shape, fineness of surface finish, subsurface stress levels, adequate load distribution, and so on, all impact the health of a component and it’s reliability.

What makes Plant Wellness Way such an effective system, is the focus is on the removing the causes of failure from occurring to begin with. When there is no risk at the Physics of Failure mechanism level, then you can be sure an asset has the greatest chance of exceptional reliability and the least risk of operating failure.

Removing Physics Of Failure Mechanisms

High equipment reliability is within the reach of every business. Reliability is malleable by choosing policies and quality practices at each level of the dependency hierarchy.

At mechanism level, set demanding quality standards for equipment parts so you get outstanding reliability during operation.

At component level, use precision that delivers long service lives to parts and apply only the highest-quality operating and maintenance practices.

At assembly level, use more robust, durable materials for components so that they take greater stresses and don’t degrade.

At the asset level, replace assets early with the newest models rather than wait too long and get numerous failures and lower productivity. Be willing to pay for higher quality equipment so your company can make fortunes from fewer failures.

For the process level, have right knowledge everywhere and only used the right practices, insuring they are done rightly.

At the business level, these requirements need to be incorporated into corporate thinking when you make engineering, asset management, operational or maintenance decisions.

The most beneficial maintenance strategies eliminate Physics of Failure mechanisms and reduce the total risk that a part carries during operation. The lower down the dependency hierarchy that good decisions are made, and precision quality controls installed, the more comprehensive is the risk control strategy.

In PWW the Physics of Failure Reliability Strategy (PoFRS) Analysis is used to select the right engineering design, suppliers, maintenance and operating requirements to most effectively remove causes of failure throughout the dependency hierarchy. It is used for all risks considered unacceptable (Figure 2) to determine what actions should be done to reduce operating risk. PoFRS follows the Stress-to-Process Asset Management Model. Starting with risks to component microstructure and working up the hierarchy, the analysis specifies the strategy, knowledge, skills and practices required in the business and asset life cycle processes to achieve component reliability.

Each mechanism cause of a critical part’s failure is identified and addressed one by one until the part’s lifetime risk control plan is complete. The risk control plan covers all that will be done during the life cycle to remove or significantly reduce operating risk. It lists the mix of design, manufacture, supply chain, operations, and maintenance activities to lower the risk of microstructure destruction and deliver high equipment reliability.