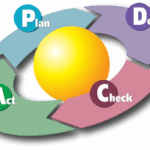

Utilizing the PDCA Methodology in Work Planning

It is well known that maintenance planning & scheduling can deliver significant improvements in the efficiency and effectiveness of the maintenance department. Maintenance planning & scheduling seems simple enough, plan the work and schedule it to be done at the most opportune time. However, why is it that the organization seem to struggle with realizing the benefits of maintenance planning & scheduling? In my experience, I have seen organizations that focus on the scheduling portion of work management, while not fully planning the work. Doc Palmer (an authority on Maintenance Planning & Scheduling) has said that you cannot schedule without proper planning. So how is it that they are scheduling work without knowing what needs to be done and what materials are required?

I recently had the pleasure to interview Doug Stangier, co-author of

I recently had the pleasure to interview Doug Stangier, co-author of  In the previous articles, we looked at what type of analysis to use to evaluate the effectiveness of the PMs and if they are cost effective. Once the PMs have been optimized to ensure they are addressing the right

In the previous articles, we looked at what type of analysis to use to evaluate the effectiveness of the PMs and if they are cost effective. Once the PMs have been optimized to ensure they are addressing the right  Would you spend $100 every week to prevent a possible issue that will result in a loss of $10? Probably not, so why is that we do that with our maintenance programs every single day? Often, PM and PdM activities are put into place without any thought to the economic impact of the

Would you spend $100 every week to prevent a possible issue that will result in a loss of $10? Probably not, so why is that we do that with our maintenance programs every single day? Often, PM and PdM activities are put into place without any thought to the economic impact of the  If you are lucky enough to have good

If you are lucky enough to have good  There has been much discussion (and often debate) around the P-F curve. The P-F curve illustrates the relationship between the warning signs that are detectable by various technology or methods and the progression of the failure. What is often not discussed and overlooked, is what happens before the

There has been much discussion (and often debate) around the P-F curve. The P-F curve illustrates the relationship between the warning signs that are detectable by various technology or methods and the progression of the failure. What is often not discussed and overlooked, is what happens before the