Doing Reliability Centered Maintenance (RCM) helps us take care of our equipment. And, taking care of our equipment is very much like taking care of ourselves.

[Read more…]Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Nancy Regan Leave a Comment

Doing Reliability Centered Maintenance (RCM) helps us take care of our equipment. And, taking care of our equipment is very much like taking care of ourselves.

[Read more…]by Mike Sondalini Leave a Comment

How to use Condition Monitoring Reports to do Maintenance Planning of the Maintenance Work Activities that will prevent Equipment Failure

This article by Peter Brown, a vibration analysis condition monitoring expert, explains how to address and action condition monitoring reports from your condition monitoring service provider.

Abstract

Maintenance Planning From Condition Monitoring Reports. Having developed the finest condition monitoring programme that provides all the data required to predict plant behaviour it is now necessary to convert that data into information and to plan it in for action by the maintenance team at a time that is compatible with operations.

[Read more…]by André-Michel Ferrari Leave a Comment

Reliability Engineers are forward and “out of the box” thinkers. They tend to bring creative solutions to customers and help them optimize asset performance. Creativity implies offering ideas and possibilities that a customer did not know of or even request. Ones that will be of great benefit to them. The role has a lot to do with marketing. It is actually marketing a better “operating” future for an organization. In this article, I share some of the approaches I have had as a Reliability Engineer on bringing the biggest reliability “bang” for the customer’s “buck”.

[Read more…]

Organizations are hastily adopting AI into their operating processes to increase efficiency, raise profits, and stay competitive. Among the hustle & bustle, the effective management of the AI projects is neglected, and teams are left to figure out retroactively how a completed AI project fits into the Business’s long-term goals.

[Read more…]by Mike Sondalini Leave a Comment

Which critical spare parts you carry in the maintenance store always revolve around how much risk your company is willing to bear. It is purely a risk based business decision. Look at the economics of the risk decisions available and go with the biggest chance of success.

—

I have a question about critical spare parts determination that I always have a problem with. I do not know if this topic is included in the online preventive maintenance training I and my team of engineers are doing with you, that’s why I am asking the question.

How can I determine which are the critical spare parts that we have to keep on stock?

by Nancy Regan Leave a Comment

by André-Michel Ferrari 2 Comments

Maintenance and Reliability professionals deal with equipment failures all the time. However, the word “failure” could have different definitions or thresholds. In order to take adequate and effective action, it is important to have clear specifications for what a “failure” truly is.

[Read more…]

Here is a story of multimillion dollar aircraft failures that could have been prevented by spending $25. But no one did the risk analysis right using a financial model of the consequences. It’s also the story of why RCM is a poor maintenance strategy selection methodology. RCM will send you to financial disaster and you won’t even know it. Learn how to decide when doing preventive maintenance is far better for business success than doing the on-condition maintenance recommended by business-destroying RCM analysis.

[Read more…]by James Reyes-Picknell Leave a Comment

Your skilled maintenance trades are a valuable resource that is often squandered by poor management and a lack of proactive approach to the maintenance of industrial assets.

This article by RBC’s Thought Leadership group on Human Capital describes a problem that many of our industrial customers are dealing with.

[Read more…]

In the 19th century, factories and mills were major concentrations of capital. Manufacturing completed for investment money, and business cases could be as closely examined as any other risky investment. In 1884, Edwin Matheson wrote about how maintenance affected accounting and business prospects in The Depreciation of Factories and their Valuation. Matheson’s book became the basis of modern views of depreciation.

by André-Michel Ferrari 2 Comments

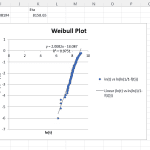

Confidence boundaries can be confusing to reliability engineering practitioners and their audience. Yet, they can play an important role in the risk-based decision-making process. When building statistical models, there is always uncertainty around the model because it is usually based on a smaller sample of the studied population. The confidence interval is the range of values you expect your model to fall between a certain percentage of the time if you run your experiment again or re-sample the population similarly. For example, using a 90% confidence boundary, one would expect 90% of the records to fall between the upper and lower confidence boundaries. As a rule of thumb, the more data you have, the more precise the model and the narrower the confidence boundaries. In essence, if we have an infinite amount of data, we will end up with a perfect model. However, this is never the case. Confidence boundaries help establish the accuracy of the model and also provide some information on the validity of the data.

[Read more…]by Miguel Pengel Leave a Comment

Every Reliability Engineer will be familiar with the Weibull Analysis. Most of us even have an Excel template laying around that we refer to!

The problem is, that when we have to handle Suspended data (e.g. components that haven’t failed yet at time of observation), the Excel sheet must use VBA in the background if the user wants a “single-button” tool.

[Read more…]by Ramesh Gulati Leave a Comment

Over thirty years ago, Steven R. Covey, renowned author and business management guru, introduced to us The 7 Habits of Highly Effective People, which presented an approach to being effective in attaining personal or business goals by aligning to what he called “True North” principles based on character ethics. This book has become a best seller, a must-read, and has sold 40 million copies worldwide.

[Read more…]by Arun Gowtham Leave a Comment

One of the common questions teams have when they first explore using Predictive Maintenance is “Is the data good enough to perform the analysis?” Answer to that question is nuanced with the reliability objective and the quality of the data available.

[Read more…]by Mike Sondalini Leave a Comment

Let a Plant Wellness Way EAM System-of-Reliability halve your Annual Maintenance Costs

The Plant Wellness Way is business paradigm to create world-class performance and results in any operation by the correct selection and use of engineering, operating, maintenance, and reliability strategy and practices.

The six IONICS steps are used to develop lifecycle asset management, reliability improvement and maintenance management strategy and activities needed for endless operational excellence. Simply identify where you are in the above process map, come in at that point, and then continue on through the process to the point where your answers are available.

[Read more…]