Should you implement the manufacturer’s recommended maintenance schedules? Not without sanity-checking them first.

Be sure you consider your operating environment, which the manufacturer is unable to do.

[Read more…]Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Nancy Regan Leave a Comment

Should you implement the manufacturer’s recommended maintenance schedules? Not without sanity-checking them first.

Be sure you consider your operating environment, which the manufacturer is unable to do.

[Read more…]by André-Michel Ferrari Leave a Comment

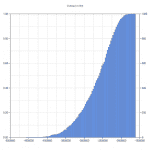

Reliability, in its academic root, is defined as the probability that a system will perform its intended function in a specified mission time and within specific process conditions. Reliability (R) is related to the Probability of Success as opposed to the Probability of Failure (F), and the relation between R and F is:

$$ \displaystyle \large R = 1 – F (t) \ \:\:\:\: \:\:\:\: (for \:mission\: time\: t) $$

In the above context, a reliability example would be: What is the probability that a centrifugal pump in a sheltered enclosure will push 3,000m3/day of sweet crude oil without unplanned failures for a period of 8,760 running hours?

[Read more…]by Arun Gowtham Leave a Comment

‘Fleet’ is the representation of a population of repairable products that are currently in use out in the field by customers. Repairable is the keyword differentiating a ‘fleet’ from commonly known consumer product ‘units’. The differentiation is key in understanding the type of reliability program needed.

[Read more…]by Mike Sondalini Leave a Comment

To be a great Maintenance Planner and Scheduler you need to know a lot about your equipment’s’ engineering, how to manage complicated projects well, use world class maintenance processes for creating equipment reliability, and a whole lot more.

Recently I was asked what skills and competencies a Maintenance Planner and Scheduler needs to master to do world class maintenance planning and scheduling.

[Read more…]by André-Michel Ferrari 1 Comment

A common error when performing a life analysis for an asset is to confuse repairable and non-repairable assets. The mathematical determination of the life characteristics for each model is different, so throwing a simple “Weibull analysis” at them might lead to the wrong results but also the loss of valuable information.

[Read more…]by Arun Gowtham Leave a Comment

The tasks of a Reliability Engineer are long & diverse. While heavily dependent on the industry one is working in, it generally involves all aspects of the Equipment – from Design to Manufacturing to Operation to Maintenance. Even though the responsibility is wide, the resources available for a Reliability Engineer within an organization are limited. Often, there are only a few Reliability Engineers managing hundreds of Equipment. Given this current situation, the arrival of AI seems like a perfect resource to complement the work.

by Mike Sondalini Leave a Comment

Getting excellent enterprise physical asset utilization and maximum asset performance needs business-wide and life-cycle-long coordination and cooperation.

By coordinating and merging business-wide data and asset historical performance records into useful asset information, you can make timely and informed decisions that safely and profitably maximize the performance and value contribution of your enterprise physical assets

To go down the path of getting operating asset optimization it is necessary that you first identify what measures will be used to determine the “optimal asset utilization” state.

[Read more…]by Nancy Regan Leave a Comment

A common step in a RCM program is to conduct a critical analysis to prioritize further analysis of those parts of the system that are critical to the operation. Yet, is criticality analysis required?

No, it is not.

Let’s explore why this may be so for your situation.

[Read more…]by Miguel Pengel Leave a Comment

Industrial operations that have operating horizons exceeding the lifespan of their assets face a crucial decision as they approach this timeline’s end (but not enough to operate the equipment until its full economically optimal life).

Specifically, they must decide whether to overhaul the asset, replace it with a new one, or rent the equipment until operations conclude. Given the numerous variables with inherent uncertainties in the financial models, how can they be confident in their decision?

[Read more…]by André-Michel Ferrari Leave a Comment

The fundamental purpose of Reliability, Availability, and Maintainability (RAM) modeling is to quantify system performance, typically in a future time interval. A system is a collection of items that operate together to produce an output, often a production value. These items can include subsystems, components, software, human operations, and more. For example, an automobile can be viewed as a system with subcomponents like the drive train, engine, gearbox, etc. In RAM models, it is crucial to consider the relationships between these items to determine the system’s final output. They have proven effective in various industries as tools for cost avoidance, decision-making, and validating assumptions made by internal stakeholders.

[Read more…]by Arun Gowtham Leave a Comment

If you’ve ever wanted to learn more about how new Digital technologies like Artificial Intelligence (AI), Machine Learning (ML), Industrial Internet of Things (IIoT), Remote Data Sensing, and Industrial Automation apply to Reliability Engineering, then you’ve come to the right place.

[Read more…]by Mike Sondalini Leave a Comment

Behind all lasting business success is the ability to make business processes work successfully. Random success in business is due to luck. But lasting success relies on knowing how to use statistical process control to make your processes more successful more often.

[Read more…]by George Williams Leave a Comment

When planning and scheduling, we need to have estimated hours to be able to schedule efficiently. Without estimated hours it makes it close to impossible to know your resource consumption. To take your scheduling efforts to the next level you need to understand the difference between Duration of job vs. labor hours required to perform the tasks.

by Karl Burnett Leave a Comment

“His Majesty Will Have A Fleet Upon The Durability Of Which There May Be Some Dependence.”

In 1763, the Seven Years’ War ended and the Royal Navy demobilized. The Earl of Sandwich left the office of the First Lord of the Admiralty for the second time. At the end of the war, Britain had 149 ships of the line. Scrapping, retirement, and storage reduced the fleet size and maintenance requirements. The navy was trying to manage a shrinking fleet with a shrinking budget.

In 1763, the Admiralty requested a report of the total value of all ships and their stores, and an analysis of the “annual cost of replacing them in cycles between twelve and sixteen years,” according to historian N. A. M. Rodger. The Admiralty also asked for an estimate for annual repair and maintenance at task work rates if they expanded the number of shipwrights to 3000. (Shipwrights were the carpenters in dockyards who built and repaired ships.)

By 1765, only 47 of the 140 ships were in good condition. The Navy Board made a plan to increase the number of ships in good condition to from 47 to 63, but the plan required three years and an extra £2,000,000. Once restored to good condition, the plan assumed that the existing shipwright workforce could maintain a fleet of 90 ships. This approach would only work if the shipwrights were allowed to maximize overtime all summer, for every summer to come…the workforce and labor budget were at maximum capacity. To actually maintain 140 ships in good condition, the shipwright workforce would have to be expanded from 3,150 to 4,200. The government did not want to expand its civilian industrial labor base at a time when it expected a peace dividend.

[Read more…]by André-Michel Ferrari Leave a Comment

The fundamental purpose of Reliability, Availability, and Maintainability (RAM) modeling is quantifying system performance, typically in a future interval of time. A system is a collection of items whose coordinated operation leads to the output, generally a production value. The collection of items includes subsystems, components, software, human operations, etc. For example, an automobile can be considered as a system with sub-components being the drivetrain, engine, gearbox, etc. In RAM models, it is crucial to account for relationships between items to determine the final output of the system. In various industries, RAM models have proven to be effective as cost avoidance or decision-making tools, as well as their ability to confirm or counter stated assumptions by internal stakeholders.

This paper highlights a non-exhaustive list of seven diverse solutions that a RAM model can bring to the organization in terms of decision-making advantages.

[Read more…]