This is the third session from the Annual Apex Ridge Reliability Seminar held in Boston.

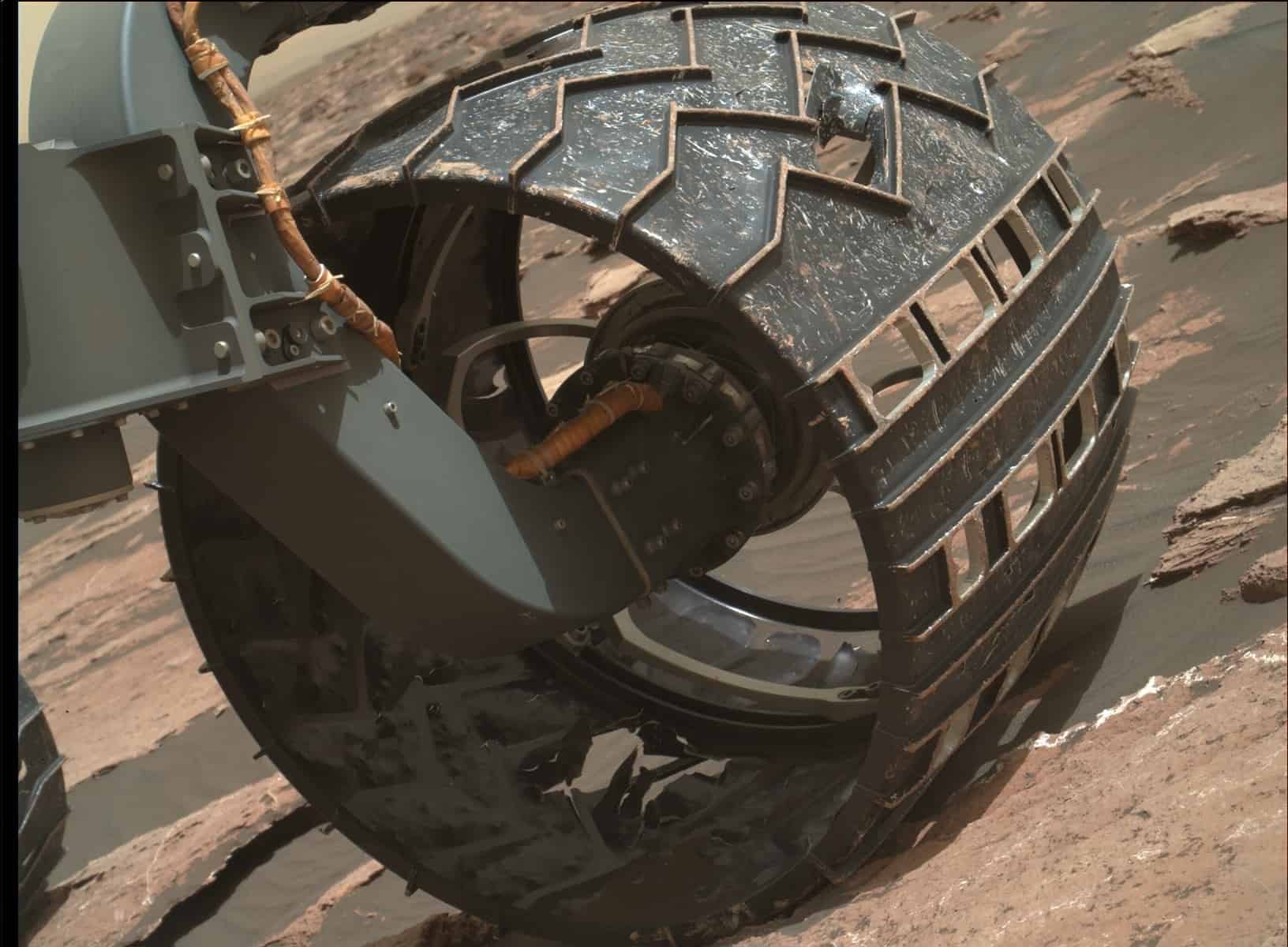

In this session, I discuss the methodology of HALT and how to connect it with program tools and objectives.

The philosophy of HALT is often misunderstood simply due to its name and acronym, “Highly Accelerated Life Testing” (HALT).

It is not an accelerated life test, it’s really not even a test. HALT is a process of increasing stress on a design to induce failures for the purpose of learning about the design and improving its robustness.

It’s a discovery process. [Read more…]