We have promoted this definition for Design of Experiments for a long time. This video provides the background of what each phrase is important. [Read more…]

Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of articles by:

by Perry Parendo Leave a Comment

We have promoted this definition for Design of Experiments for a long time. This video provides the background of what each phrase is important. [Read more…]

by Perry Parendo Leave a Comment

When testing, it is good to know your options. The Advanced tools of Design of Experiments are good to consider. What are they, why should you consider them, and when should they be used. Those are the topics we will discuss in this video. [Read more…]

by Perry Parendo Leave a Comment

How do you know if YOU need robustness? It is a combination of testing and analysis. Can you afford it? How do you decide? This video helps set the stage for this decision. [Read more…]

by Perry Parendo Leave a Comment

I know what Robust Design is, but do companies really need it? If so, who needs it and why? This video helps address that question. [Read more…]

by Carl S. Carlson Leave a Comment

Can you take into account reliability or durability functions in an FMEA? How can this be done? A reader asks this question, and it is discussed and answered in this FMEA Q and A article.

“A prudent question is one-half of wisdom.”

Francis Bacon

by Perry Parendo Leave a Comment

When your engineering project struggles, how do you respond? This video provides a sports analogy to the situation. Get back to the fundamentals – and Design of Experiments can be part of that process.

www.PerrysSolutions.com [Read more…]

by Perry Parendo Leave a Comment

After years of consulting, what motivates us now? This video discusses those areas of interest for us. Constant learning and challenge keeps us going! [Read more…]

by Perry Parendo Leave a Comment

Why did we start the company – and why this specific company. This video provides the answer. www.PerrysSolutions.com [Read more…]

by Perry Parendo Leave a Comment

Many times, a complete analysis is not performed with DOE testing. However, the learning value is substantial for model building situations and only takes a small amount of additional time if you know what you are looking for. In this video, we give an overview of the key items we look for to develop break throughs in product and process development. This same process has been used for the majority of our 25+ years of DOE experience. [Read more…]

In this week’s FMEA problems and solutions article, the intermediate problem challenges readers to prioritize a series of RPNs (with their corresponding S, O, and D). In the advanced problem, readers are asked to weigh in on a fictitious debate between advocates of traditional RPN, and advocates of criticality assessment, using only severity and occurrence.

If you haven’t yet read the article titled “Prioritizing risk for corrective actions in an FMEA – Know before you go!“, you can access it by clicking on the link.

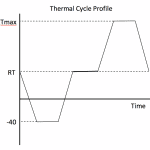

Reliability and durability are essential in today’s competitive market place. However, component reliability verification tests and system durability tests take a long time, cycles, or miles to complete. This puts these tests in direct conflict with program timing, product development budgets, and limited testing resources. To minimize this conflict, it is essential to accelerate these tests.

by Perry Parendo Leave a Comment

Taking Your Business to Next Level

A radio interview with Perry Parendo.

This video provides some of our learning and observations regarding renewing your business or renewing your career. www.PerrysSolutions.com [Read more…]

by Perry Parendo Leave a Comment

Needs and How to use an Expert for your Project

Finding an expert for your project is important. Knowing what traits they need and how to employ them will lead you to improved opportunity for success. We at Perry’s Solutions, Inc. have these key traits and exist as a business because we are often being used in this role – previously as a corporate employee and now as a consultant. [Read more…]

by Dennis Craggs Leave a Comment

Extended bogy testing builds on test to bogy (TTB), discussed in a prior article. TTB focused on calculating the number (N) of parts tested to one life bogy, with 0 failures allowed, to a specified reliability (R) and confidence (C) levels.

Using TTB to verify conformance to high reliability and confidence targets requires very large sample sizes, increasing testing cost. The capacity to test large samples may require large facility capital expenditures. Also, the zero failures allowed paradigm removes the opportunity to learn about product failure modes and the opportunity to improve the product through design or manufacturing process changes.

This article focuses on extended bogy test plans as an alternative to TTB.

by Perry Parendo Leave a Comment

Design of Experiments classes always talk about Resolution III and higher designs. But what is a Resolution II design? We show what it is – and show that it is actually used quite a bit! Should be used with caution as it does not provide understanding.

www.PerrysSolutions.com [Read more…]