Innovative situations require strategic testing to reduce risk. The points reviewed summarize our approach when we have performed this activity. It ends up being the heart of the development plan. [Read more…]

Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of articles by:

by Perry Parendo Leave a Comment

Innovative situations require strategic testing to reduce risk. The points reviewed summarize our approach when we have performed this activity. It ends up being the heart of the development plan. [Read more…]

by Perry Parendo Leave a Comment

This video gives some tips regarding networking. It applies to finding a job or for obtaining clients in a consulting business.

This was created for the large number of people I know who have been displaced from a job. Many wanted advice based on my experiences and with my daily effort to build my consulting business. Not being able to have lunch with everyone, I created this video to help them get started. It has been helping people, so hope you can find value. It may also turn into a book at some point.

[Read more…]

Note from author:

Since this article was originally published, there are subsequent articles in the “Inside FMEA” series that further describe better approaches than RPN to risk prioritization. Here are links:

Is There a Better Way Than RPN?

Risk Prioritization in FMEA – a Summary

Is There a Better Way Than RPN?

Text of the original article:

One of the most important steps in FMEA procedure is prioritizing risk for corrective actions. As soon as Severity, Occurrence, and Detection ratings have been determined for each failure mode and associated cause, the next step in an FMEA is to prioritize the risk and identify which issues need corrective actions. This step has been misapplied more often than any other step in the FMEA process.

“The perfect is the enemy of the good.”

Voltaire

Test To Bogy Sample Sizes

Introduction

Reliability verification is a fundamental stage in the product development process. It is common for engineers to run a test to bogy (TTB). What sample size is required for a TTB?

Reliability Testing

Reliability is the probability of a part successfully functions under specified life, duty cycle and environmental conditions. Many functions are specified during the design process. Each reliability test will be focused to validate a specific function. The targeted verification level depends on the criticality of the function and potential failure modes. The life could be specified as a count of cycles, an operating time, or perhaps a mileage or mileage equivalent. The duty cycle is a description of how the device is used. Environmental stresses are generally included in the test.

by Perry Parendo Leave a Comment

An example of how we work with people. While a basketball example, it shows many traits that apply equally to engineering and new product development. [Read more…]

by Perry Parendo Leave a Comment

Coaching in Business Problem Solving – Radio Interview

This radio interview combines the principles of business problem solving and basketball coaching. [Read more…]

Introduction

When planning a test on a continuous variable, the most common question was “How many should I test”? Later, when the test results were available, the questions were “What is the confidence?” or “How precise was the result?” This article focuses on planning the measurements of a continuous variable and analyzing the test results.

by Perry Parendo Leave a Comment

Communication is essential for coaching and team success. This framework has helped us work with players in the short time of a basketball camp. A similar approach is used when working with business clients. [Read more…]

by Perry Parendo Leave a Comment

How does someone address the critical question of how many parts are needed for a test? We cover the balance between math and experience. [Read more…]

by Carl S. Carlson Leave a Comment

What if a production worker uses a different cleaning method for an assembly operation than was outlined in the operation work instructions, and the result is customer complaints and field issues. How could this be addressed in a Process FMEA? This question is discussed and answered in this FMEA Q and A article.

“I think that probably the most important thing about our education was that it taught us to question even those things we thought we knew.”

Thabo Mbeki

by Dennis Craggs Leave a Comment

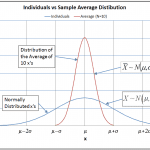

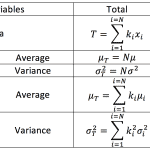

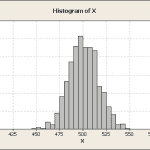

In some of my articles, I have referred to The Central Limit Theorem, a development in probability theory. It can be stated

“When independent identically distributed random variables are added, their normalized sum tends toward a normal distribution (informally a “bell curve”) even if the original variables themselves are not normally distributed.”

We can apply this principle to many practical problems to analyze the distribution of the sample mean. In this article, I provide graphical and mathematical descriptions and a practical example.

by Perry Parendo Leave a Comment

Very often I hear New Product Development teams say “we are almost there.” Yet they can be in this condition for months or years. Using a DOE approach can accelerate to the design point. When something has hit the wall, this has been the best approach I have found to create a break through in development. [Read more…]

by Dennis Craggs Leave a Comment

How many responses are needed for a survey? This question requires specifying the desired confidence and the accuracy of the survey results.

A Bernoulli trial is an event that has two possible outcomes. Consider the case where the only possible outcomes are success or failure. Let the probability of a success is p and the probability of failure equals q. The probabilities of all possible events must equal 1, so q = 1-p. These relationships are expressed mathematically as

Can you find this common error in detection ranking in the intermediate problem in this article? In the advanced problem, the topic of an in-service detection scale will challenge the most experienced readers.

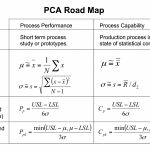

In prior articles on process capability, sample statistics and SPC statistics were assumed to be population parameters and ignored sampling variability. This article reviews the analytic methods that can be used to develop confidence bounds on the process capability indices.

The Pp index calculation requires an estimate of the parameter σ. The index is calculated as: