In all production facilities, the success of most business operations is closely tied to the performance of their maintenance operations. On a busy plant floor, for example, all it takes is for a critical machine to breakdown mid-production and the ripple effects begin; from lost deadlines to stressed staff, wasted materials, and so on.

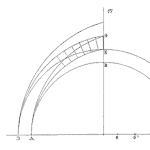

Identifying exactly when an asset will fail still remains a big priority and “tools” like the p-f curve are here to guide us in the right direction.