ISO 31000:2018 is the world’s foremost risk management standard. The Standard provides guidelines, principles, framework, and a process for managing risk.

The standard explicitly states that it should NOT be used for certification or registration. But, it is.

So, what’s going on? We can only speculate. But, here goes:

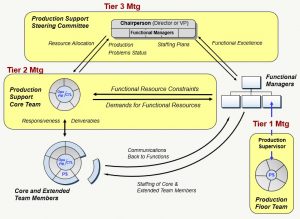

We now live and work in VUCA (Volatility, Uncertainty, Complexity, Ambiguity) time. More companies want to be RISK audited and certified by an independent Certification Body (CB).

And, more CB’s are working to use ISO 31000:2018 as a standard for certification. [Read more…]