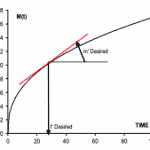

Using Failure Data to Drive Sustainable Improvements

If you are lucky enough to have good failure data history in your CMMS, you are one of the few. But even if you have the data, can you use it to make a difference to your organization? Obviously, the data can be used to perform certain reliability engineering analyses, but what can those without reliability engineering experience do with the data?

If you are lucky enough to have good failure data history in your CMMS, you are one of the few. But even if you have the data, can you use it to make a difference to your organization? Obviously, the data can be used to perform certain reliability engineering analyses, but what can those without reliability engineering experience do with the data?