Everyone wants excellence and continuous improvement, but what does optimization mean? And how do you get there? This video covers two basic optimization methods and how we blend them for Robust Design. [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Perry Parendo Leave a Comment

Everyone wants excellence and continuous improvement, but what does optimization mean? And how do you get there? This video covers two basic optimization methods and how we blend them for Robust Design. [Read more…]

by Greg Hutchins Leave a Comment

In our aging societies with a work force ranging from Baby Boomers through Generation Xers to Millennials the ‘D-Word’ may summon up images of stoical sergeant-major types shouting and barking and removing any freedom of thought or act. Discipline is variously defined but it is generally understood to be ‘the ‘training that produces orderliness, obedience and self control to follow rules‘ and, operatively, if rules are broken ‘chastising or punishing‘. . [Read more…]

by Fred Schenkelberg Leave a Comment

Sometimes a process doesn’t happen one step at a time. Sometimes, a problem we’re trying to solve has many moving and interacting elements.

Mind Mapping is a technique to capture those scattered thoughts, those non-linear processes, those myriads of interactions and dependencies. It’s a tool that is useful for brainstorming, organizing, and problem-solving. [Read more…]

by Doug Plucknette Leave a Comment

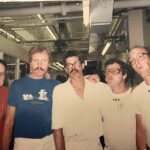

The first person I selected to write about is one who I consider a mentor. I met Marc Zimmerman in February of 1981, at the time he was a Journeyman Pipefitter in Kodak’s Polymer Department and I remember watching him work, making precise gore cut fittings and just being in awe of craftsmanship it takes to calculate, lay-out, cut and assemble these pieces. [Read more…]

by Perry Parendo Leave a Comment

Coach Dean Smith always used this phrase with his teams and his teaching. It is how I focus my coaching, but also how I consider New Product Development. Would this mix be valuable for your organization and your career? [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Joseph Paris (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Transformation… I am hearing more and more talk about how companies are seeking to transform themselves, or that they are launching a transformation initiative. And as expected, there is the corresponding increase in transformation conferences, symposia, articles and books.

But what is “transformation”? [Read more…]

by Fred Schenkelberg Leave a Comment

There are two common uses for a check sheet. First, to summarize historical data, or second, to collect observations. A byproduct of creating a check sheet is team agreement on definitions of categories and observation procedures.

The investment is minimal other than thinking about how you want to view the data, and what data to collect. [Read more…]

by Adam Bahret Leave a Comment

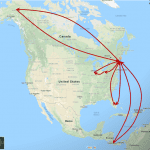

In the past five weeks I have been to Miami, Orlando, Cleveland, Chicago, Fairbanks Alaska, Fortuna Costa Rica. For one stint of that I went Fairbanks to Boston to Costa Rica in a 24 hr period. I walked into my home dropped the Alaska suitcase, grabbed the prepacked Cost Rica suitcase, slept for 6 hours ,and was back on a plane 13 hrs later. I think that qualifies as a HALT test considering the lowest temperature I experienced in Fairbanks (Arctic circle edge) was -30F on top of a mountain and then 85F in Costa Rica in the Rainforest.

So why did I do all of this? Because it’s me and it seemed fun.

by Dennis Craggs Leave a Comment

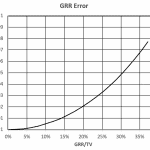

Most of us rely on accurate measurements. If these measurements are unreliable, then our decisions could be based on false information. How can we have confidence in our measurements?

The purpose of a measurement system analysis is to determine if a gauge is fit for use. This means that we can rely upon the measurements to give us a true indication of the parameter being measured. Our decisions will not be affected by erroneous data. So how can we know the quality of our measurements?

[Read more…]

by Doug Plucknette Leave a Comment

I’ve always considered myself to be somewhat lucky in life. I survived being hit head on by a car when I was five years old. I grew up in a small town in Upstate NY that had little to do in the form of entertainment but a lot to offer those in search of a sound middle class life. While I still live in that same town it has transformed from a farming community to a suburb of Rochester. I have raised my children in this same town my parents and grandparents called home and my grandchildren are being raised here as well. While life is good in our Village whose slogan is “Someplace Special” the opportunities available to my generation aren’t what they used to be. Today, it’s tough to be lucky.

When I look back, I don’t have to think too hard to know why life turned out so good. I learned a trade. [Read more…]

by Perry Parendo Leave a Comment

Case studies always have good endings – but this one was not looking good. With some insights, we found an unexpected issue. This provided an important answer for a struggling manufacturing process. [Read more…]

by Robert Allen Leave a Comment

Our previous article identified several forms of waste, specific to completing tasks, as detailed by the following table:

Keep in mind, by focusing on tasks, this table assumes several things:

by Greg Hutchins Leave a Comment

All organizations regardless if they are public or private, for profit or not for profit, large or small face uncertainty. Uncertainty results in risks. More organizations will face uncertainty in the design, implementation, and assurance of their Quality Management System (QMS), Environmental Management System (EMS), Information Security Management System (ISMS), and most ISO management systems. The critical organizational challenge over the next decade is how organizations will address and treat the risks that result from the uncertainty. ISO 31000:2018 was developed to address this growing uncertainty. [Read more…]

by Fred Schenkelberg Leave a Comment

When you have a scattering of ideas or suggestions, you can use affinity diagrams to organize and group them.

Affinity diagraming is a simple way for an individual or (better) a group to quickly gather and organize a large number of disparate concepts, ideas, suggestions, etc. It is a natural activity after a brainstorming session. [Read more…]

by Adam Bahret Leave a Comment

Anyone who knows me knows I love modifying things. I always feel there is a better design. This is the goal of a reliability engineer at heart. I enjoy sports and I enjoy running. I do believe that we were born to run. If you look at the human body that is clearly what it was built for. Our big toe faces forward, which makes them no longer good for gripping things like branches. But it does make them great for landing a foot in forward motion. We have extremely long legs in proportion to our bodies compared to all other primates. We are slender which provide a great ratio of surface area to mass for cooling. The ability to sweat without hair is a great temperature control method as well. We are also the only mammal that can uncouple our breathing to our running pace because we are bipeds. This let’s us optimize our breathing for long distance.