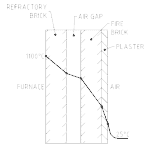

Heat is energy and its nature is to flow from a state of high excitement to one of low excitement. Heat is transferred from a hot place to a cold place by convection, conduction or radiation. This article explains the three modes of heat transfer and provides simple examples of each. Methods to reduce and increase heat transfer are also presented. [Read more…]