Before you go on, please have a look at British comedian John Oliver’s video on infrastructure – https://www.youtube.com/watch?v=Wpzvaqypav8.

OK, if you are reading this and still haven’t watched the video … please go back and try again. You can do it.

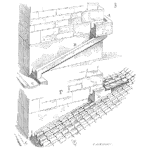

If you haven’t watched the video by now, then I concede defeat. In short, the video is a humorous take on the state of US infrastructure. Particularly bridges. Bridges have been collapsing with alarming frequency in recent years. And after much political wrangling there is still no plan to pay for fixing crumbling columns, spans and struts. It is not as if the federal and state governments don’t know how bad things are (again … watch the video).

Oliver proposes a perhaps novel reason for all of this. [Read more…]