I am frequently asked to review engineering reports and documents. And I am continually baffled with how many engineers want to ‘take their reader on a journey’ as opposed to getting to the main point. These engineers write documents where you have to read every single word to work out what they are trying to say. But having a final reveal is never a good thing in any technical document. [Read more…]

Articles

Find all articles across all article series listed in reverse chronological order.

Milestone Achieved!

Inside FMEA has Achieved its First Milestone!

This article culminates the first major milestone in the Inside FMEA series of articles: the “FMEA Fundamentals Series.” The next series is called: “FMEA Preparation Series.”

“Remember to celebrate milestones as you prepare for the road ahead.” Nelson Mandela

[Read more…]

Interpreting Design of Experiments

How do you interpret a DOE? With a few principles it becomes easier to understand. Very important to consider the intangibles. It is not a pure mathematical problem. It is critical because this is where the value from the testing shows up! [Read more…]

Discipline

Discipline, look it up in the dictionary and you will find the following definition; the practice of training people to obey rules or a code of behavior, using punishment to correct disobedience.

People tend to get nervous when the word Discipline pops up at the top of a presentation. Truth is there are several definitions to this word. As an example, Discipline is also a branch of knowledge one studies in higher education. [Read more…]

City Risk Index and ERM

Guest Post by James Kline (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Recently, Lloyd’s of London in conjunction with the University of Cambridge Center for Risk Studies, published the results of their global risk analysis. Lloyd’s document is entitled “Lloyd’s City Risk Index: Executive Summary”. Cambridge has entitled theirs “Cambridge Global Risk Outlook 2017”. This is their second risk assessment. The first was published in 2004.

The index is a ten-year projection based on twenty-two threats to 300 hundred of the world’s leading cities. The 300 cities account for half of the world’s Gross Domestic Product (GDP). This piece discusses the results of the study and its implication for the application of Enterprise Risk Management (ERM). [Read more…]

The Big Bang — Starting and Stopping Equipment Under Load

The Big Bang – starting and stopping equipment under load. When a machine starts-up its parts move from zero speed to operating speed in a short time (the reverse when stopping). During this short period the biggest forces that the machine experiences act on its components. If during the start-up or slow-down the product or process loads are added to the machines own self-loads the forces acting on the machine’s parts are horribly magnified. If these impulse forces exceed the machine’s design allowance, or cause gradual fatigue, then the stressed parts will shatter without warning. [Read more…]

Flying Back in Time

I had the unbelievable pleasure of piloting a retired 1953 T-34 Air Force plane. The plane is owned by a friend and it has recently undergone a full restoration. A few year ago this model was grounded by the FAA due to an unusual issue. After the investigation the fleet was cleared to fly and the root cause was ruled as “mis-use.” Something many of use may not consider enough when creating our own products.

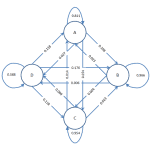

Telematics Data – State Analysis

Introduction

A state variable is a parameter that is categorized into a countable number of defined states. Examples would include transmission gear states, PRNDL positions, ignition switch states, and others. Sometimes continuous variable, like pedal positions, may be binned into discrete states to be displayed as a histogram. State change timing is unpredictable since vehicle operation is highly variable. A way to deal with this data is Markov Analysis.

A Tool to Assist in the Process of Understanding a System

We have promoted this definition for Design of Experiments for a long time. This video provides the background of what each phrase is important. [Read more…]

Standardize Your Maintenance and Reliability Program

Utilizing Recognized Standards in Your Maintenance & Reliability Program

Imagine being able to easily share information across sites or even organizations. Or how about utilizing a risk management framework that is recognized and agreed upon by all in the organization. Benchmarking made easy? Standards enable this. [Read more…]

What Happened to General Electric?

General Electric (GE) for many years was the go-to company for competitiveness, efficiency, and innovation. General Electric’s tagline was ‘Imagination at work.’

GE more recently has had a number of troubles. GE’s profitability tanked. GE is selling many of its assets and divisions. GE was also taken off the Dow after 110 years. [Read more…]

Rotating Shafts Under Bending Stress

Rotating shafts under bending stress. It is common to transmit motion using rotating shafts. The shafts are mounted in bearings and turned by force through a drive arrangement. The shafts usually also carry a load. These loads cause bending and the shaft reacts by producing counter stresses within itself. Provided the reactive stresses are within the shaft’s strength range it will take the load. But if the stresses are greater than what the shaft can take it will bend. Even if the stresses are below the load limit but fluctuate, it is possible that the shaft will break from fatigue. The point of highest stress can be found by looking at the arrangement of the shaft supports and loads and calculating the forces and stresses.

[Read more…]

Millennials and Management: It Is Your Fault They Don’t Stay at Your Company

I was presenting at the Aerospace Conference earlier this year, where something astounding happened. I was talking to the audience about ‘organizational culture’ and my experiences working with a small satellite manufacturer to help them improve their product’s reliability.

At the end of my talk, I was asked the following questions (which I have done my best to remember verbatim):

How do you accommodate the young engineers of today, who will only stay at one organization for a couple of years before moving on? Research has shown they typically leave within three years – so why should we invest time and effort into them?

If you are a team leader or manager that is searching for the answer to this question, I have some potentially bad news for you:

It is not them … it is you. [Read more…]

Reliabilty Culture in Stuttgart

I just returned from a great conference in Stuttgart called “Reliability Days.” I presented on some new concepts and techniques with regard to assessing and improving reliability culture in the product development process. Enjoy the presentation.

-Adam

Considering Advanced DOE Designs

When testing, it is good to know your options. The Advanced tools of Design of Experiments are good to consider. What are they, why should you consider them, and when should they be used. Those are the topics we will discuss in this video. [Read more…]

- « Previous Page

- 1

- …

- 179

- 180

- 181

- 182

- 183

- …

- 270

- Next Page »