What you will learn from this article.

- The types of forces developed in a turning agitator.

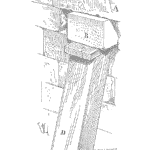

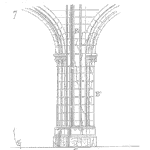

- Gearbox position and configuration for long-life.

- Bearing arrangements to minimise gearbox loading.

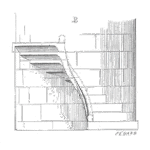

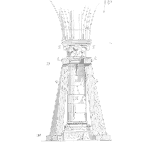

- Simple, strong agitator support arrangements.

- Vapour seals are needed to stop fumes escaping.

- Lots of low maintenance selection and design tips.

Agitated vessels and tanks are common throughout the process and chemical industries. A properly sized agitator with correct proportions to suit the tank will deliver well-mixed product. A correctly sized gearbox with well-chosen bearings and bearing arrangements will need only regular lubrication while giving years of trouble free service. [Read more…]