Introduction

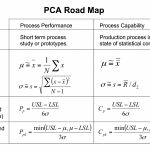

In prior articles on process capability, sample statistics and SPC statistics were assumed to be population parameters and ignored sampling variability. This article reviews the analytic methods that can be used to develop confidence bounds on the process capability indices.

$-P_p-$ Index

The Pp index calculation requires an estimate of the parameter σ. The index is calculated as: