Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Rethinking Risk and Uncertainty

What is risk? Think about it before you leap to answer. Do we really know and understand risk? Some facts to consider:

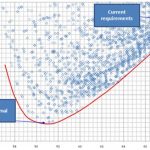

- Risk is not static, it is fluid.

- Risk probes for weaknesses to exploit.

- Risk, therefore, can only be temporarily mitigated and never really eliminated.

- Over time risk mitigation degrades and loses effectiveness as risk mutates, creating new risk realities.

Risk management requires that you constantly monitor recognized risks and continue to scan for new risks. This process cannot be accomplished with a ‘one and done’ mindset. Risk needs to be looked at in three dimensions and perhaps even four dimensions to begin to understand the “touchpoints” and aggregation of risk, potential to cascade, conflate and/or come to a confluence. [Read more…]