Should I Become a CRL, CMRP, or CRE?

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Fred Schenkelberg 6 Comments

by Doug Plucknette Leave a Comment

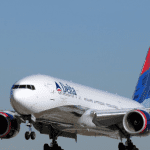

Yet another example of why it’s important to understand the failure modes that make your system vulnerable to complete shutdown. Delta Airlines is learning this lesson the hard way today after having to inform customers around the world that all of its flights would be on hold or even canceled due to a “system wide outage”.

Delta listed the cause for the outage as a power failure near its world-wide office location in Atlanta, Georgia while those at Georgia Power believe it was the failure of Delta’s equipment that caused the power outage.

While each company points the finger at the other, the reality is Delta’s customers around the world are sitting at airports or at home wondering when the problems will be resolved and when Delta will be able to accommodate their travel needs.

by Perry Parendo Leave a Comment

There are several reasons why DOE could be used. This video will provide those reasons and provide the support behind it. The reasons are beyond the traditional ideas. [Read more…]

by Robert Allen Leave a Comment

In this article we’ll explore the topic of requirements, and attitudes about identifying requirements before the design work begins.

In my experience, I’ve had design resources literally state “I hope there are no requirements”. (Unconstrained design and no requirements certainly made this designer’s job much easier.)

There are several other reasons requirements are sometimes neglected:

by Greg Hutchins Leave a Comment

Guest Post by James K. Kline (first posted on CERM ® RISK INSIGHTS – reposted here with permission)Reputational Risk and ERM

It is estimated that an organization’s reputation accounts for over a quarter of its market value. As such managing reputational risk has become an important issue for C-Suite members. This piece examines the issues surrounding reputational risk and how an Enterprise Risk Management (ERM) approach can help manage this risk. [Read more…]

by Mike Sondalini Leave a Comment

Life cycle costing (LCC) is a way of analysing equipment purchase choices. If the analysis is done right and all factors are addressed, and the information is good, you would select the item that cost the least amount to own (buy and use) over its working life. This piece of equipment when compared to other suitable items would perform its lifetime service at least total cost to the organisation. [Read more…]

One of the best pieces of career advice that I have ever heard is to treat your career as a company, of which you are the CEO. And like any company, your career will need a guiding principle that will help you stay focused on your purpose. Companies today would not think of operating without a mission statement to guide them. However, too many of us skip this critical aspect of running our own careers. [Read more…]

by Fred Schenkelberg Leave a Comment

This is part of a short series on the common life data distributions.

The Birnbaum-Saunders distribution is a univariate continuous distribution. This short article focuses on 7 formulas of the Birnbaum-Saunders Distribution. This distribution was designed to model the Miner’s rule, thus allowing for non-constant fatigue cycles through accumulated damage.

If you want to know more about fitting a set of data to a distribution, well that is in another article.

It has the essential formulas that you may find useful when answering specific questions. Knowing a distribution’s set of parameters does provide, along with the right formulas, a quick means to answer a wide range of reliability related questions. [Read more…]

by Perry Parendo Leave a Comment

We have resolved many manufacturing issues. Why do I need DOE to do this? How can we better get to root cause? Each section below contains a 2-minute video to expand on the topic provided.

Design of Experiments is the best tool for resolving problems when our science and experience fails us. Even if we are right, we also need to prove our approach works to others. Today that includes proof with statistical confidence. We need to be efficient to reduce excessive prototypes, scrap and downtime.

A few months back, I wrote a blog resulting from a conversation I had with a group of Maintenance Technicians who were attending the International Maintenance Conference (IMC) in 2011. While the group was enjoying the conference and learning some new things, the general consensus was that they felt they would not be able to apply the tools and techniques they were learning because “management will say they support reliability, but when it comes right down to it, talk is cheap.”

by Greg Hutchins Leave a Comment

Guest Post by Greg Carroll (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

In my 2013 book Mastering 21st Century Enterprise Risk Management: Firing Dated Practices | The Best Practice of ERM | Implementation Secrets I quipped “just as the Wild West of the 1890’s had disappeared without trace by the Roaring 1920s, so too will the business world of the 1990s, be long forgotten by the 2020s”. Just 5 years on and not only has the world changed emphatically but the rate of change is accelerating. [Read more…]

by Mike Sondalini Leave a Comment

Properly designed o-ring grooves and properly installed o-rings stop the passage of pressurised liquids or gasses. Flexibility while being deformed under pressure is their greatest sealing advantage. O-Ring Design and Materials O-rings are made of elastomeric materials such as rubbers and plastics. They deform under pressure and then return back to their original shape once the pressure is removed. They also accept the movement of mirror-finish shafts while deformed by pressure. Usually they are shaped like a rubber elastic band of round cross section, but they can have rectangular, trapezoid and even ‘+’ shapes depending on the application. The material, internal diameter (ID) and cross section diameter specify o-rings of round cross section. [Read more…]

by Robert Allen Leave a Comment

In recent articles I focused on a ‘linear’ approach to product development by understanding customer needs, establishing requirements (“what the design provides”), establishing a conceptual design, etc.

In this article, I’ll discuss a framework whereby an idea for a product or design might kick-off the process.

Also, rather than a commercialized product, we will assume our goal is to successfully demonstrate the idea’s feasibility. (This is common for a start-up company, where the business model might be to demonstrate product success with a goal of obtaining more venture capital, or to sell the intellectual property. Alternatively, a large company might want a separate idea development process that takes invention off the critical path.)

by Fred Schenkelberg 2 Comments

This is part of a short series on the common life data distributions.

The Beta distribution is a univariate continuous distribution. This short article focuses on 7 formulas of the Beta Distribution.

If you want to know more about fitting a set of data to a distribution, well that is in another article.

The Beta function is not used to describe life data very often yet is used to describe model parameters that are contained within an interval. For example given a probability parameter constrained from 0 ≤ p ≤ 1 the use of the Beta distribution is well suited to model such a parameter.

The Beta distribution is also known as a Pearson Type I distribution. [Read more…]

by Adam Bahret Leave a Comment

Modular subsystems in a wheelhouse technology may or may not be a staple in your industry. There are some industries where they are not a standard practice and there are industries where without them, you can’t be a competitor. Of course there is everything in-between.

First let’s define what a modular subsystem is for this discussion. A modular subsystem is an assembly that is designed to be integratable into multiple products. For the automotive industry this could be a transmission. Each car model a manufacturer makes does not have a unique transmission design. There may be six transmission types that cover 20 car models.