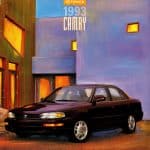

Toyota just issued a recall of all 1993 Toyota Camrys. Tokyo- “It’s simply time for drivers to move on.” Then added “We understand that the 1993 Camry was tremendously dependable, but, honestly, there’s just no excuse for driving a 24-year-old car at this point. You could have updated features like bluetooth and a backup camera” said Toyota spokesman Haruki Kinoshita. While Toyota is reportedly confining its recall to the 1993 Camry, it also issued a warning to owners of 1994 to 1998 models alerting them to the fact that they were really starting to push it.

I can’t take full credit for that joke. But like most satire it is inspired by a reality. I actually just walked by this car in a parking lot a few hours ago. [Read more…]