What is Enterprise Risk Management (ERM)?

ERM is a relatively new concept. There is a robust discussion among experts what it really means. Common ERM elements in most definitions include: [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Greg Hutchins Leave a Comment

ERM is a relatively new concept. There is a robust discussion among experts what it really means. Common ERM elements in most definitions include: [Read more…]

Equipment reliability studies show that the likelihood of failure increases the more often machinery is disturbed. The chance of something being done wrong rises every time an item of plant is worked on. Nothing may go wrong the first time or the second time but with each additional disruption there is an increasing possibility that an error will be made.

Simple, fast and uncomplicated access to individual items of plant and equipment means higher plant availability and longer time between failures. [Read more…]

by Fred Schenkelberg Leave a Comment

Once reliability risks have been identified and analyzed, we have to do something.

Well, not really.

If the risk is acceptable to the stakeholders, then we can simply continue with the current plan and monitor or any new risks or changes in our understanding of the existing risks.

Risk mitigation is a ‘system, process, or investment to control the likelihood or consequence of a risk.’ This is according to the glossary of risk terms in ISO 31000: Enterprise Risk Management. In many cases, the risk is unacceptable and will require mitigation. [Read more…]

In honor of the fast approaching holiday season, let’s start the week off with a laugh or two, I have listed some of the sure-fire signs that your company may not be ready for this reliability stuff. I have to say that in my first 5 years working as a consultant, I wasn’t prepared for some of the things folks would tell me while working on site, and there were times I actually laughed when I should have just bitten my tongue. I once asked a manager if their equipment was reliable; he pondered the question a minute and replied, “It is some of the time.”

Tell me: how do you not laugh when someone says that with a straight face? [Read more…]

In these series of questions, a reader asks about whether system FMEAs in the medical device industry should include human interactions, and the difference between system and application FMEAs.

“The art of proposing a question must be held of higher value than solving it.” Georg Cantor

The Maintenance Planner / Scheduler is known as the coordinator of the maintenance department. But what if they are unsure of the priorities of the department or business? It has the potential to increase overtime, planned downtime and increase costs. That is why this series continues with the Maintenance Planner / Scheduler. With the Planner / Scheduler clear on their roles and responsibilities, the technicians can deliver the right amount of care. [Read more…]

by Adam Bahret Leave a Comment

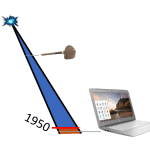

If you had to section the history of reliability into only two periods I believe the dividing point would be around 1950. The first section, stone age to 1950, the “Robust” era; 1950 to today, the “Margin” era. In the robust, era reliability concerns were addressed by creating a design that was orders of magnitude stronger than required, “over-engineered”. This protected against the variability of fabrication, use, and environment. If it was made sloppily with low tolerances, it still worked; Used for an unintended purpose, still worked; Left out in the snow, dropped in the river, run over by a horse, buried in the sand; still worked. [Read more…]

A fluid is either a liquid or a gas. In industry, they are piped from storage to the point of use. Correct design and installation of the piping system minimises pressure loss and improves the behaviour of equipment and processes.

This article briefly explains what happens to fluids flowing through pipes. [Read more…]

We have conducted hundreds of risk assessments in a number of sectors from homeland security to pension funds to Parks and Recreation departments. We have a number of hard lessons learned. These are some common mistakes we have made and seen: [Read more…]

What happens when you power up an electronics device with clocked circuits?

Well you have a clock running and you have clocked circuit elements, also known as sequential circuits. Latches, registers, basically any “memory” element. What could interfere with testing?

Do you know the state of that “memory element” when you start?

Heck No!

That’s a problem. [Read more…]

by Fred Schenkelberg Leave a Comment

Customers want the benefits created by your product. They want the time savings, the reduced yield loss, they want simplicity, coolness, speed, etc.

Customers buy your product to solve a problem, they do not buy it to simply enjoy the features. The features have to do something of value. They have to provide a benefit.

If your product fails, the feature doesn’t work. Customers do not realize the benefit they expected.

In short, your customer wants your product to work as expected. When asked a customer will tell you they do not want to have product failures. [Read more…]

by Les Warrington Leave a Comment

I wonder how many product tests have been undertaken and nothing has been done with the results? Maybe development activities have moved on before any results are available? Maybe the test results didn’t provide the answers that were needed? Maybe the test wasn’t focused on the critical issues. In other words, cost, time and resources were wasted.

I will present a better way to ensure value is delivered and test results are acted upon. [Read more…]

Working with product engineers to develop a reliability test early in a program can be a satisfying experience. My interactions with the product engineers are the most fruitful when there is mutual respect. I ask the product engineer questions about his goals, the product features, the supplier, and rely on his product expertise. I like to examine prototype parts and review an engineering drawing or the circuit diagrams.

A good example was when a product engineer, let’s call him Jim, approached me to develop a safety switch reliability test.

by Doug Plucknette Leave a Comment

Having visited hundreds of manufacturing plants in the last 15 years, someone recently asked me if there were any traits the most reliable plants all had in common. I have listed below the top 5 signs of a reliable plant. [Read more…]

The maintenance manager is known as the leader of the maintenance department. But what if they are unclear on where they are going or need to do? It has the potential to derail the entire department. That is why this series is going to start with the maintenance manager. Once they are clear, the rest of the team can follow.

If you followed the steps in first post of the series, you would be ready to review the roles & responsibilities across the department. This post takes the next step of breaking down the individual role of the maintenance manager to help you on that journey. [Read more…]