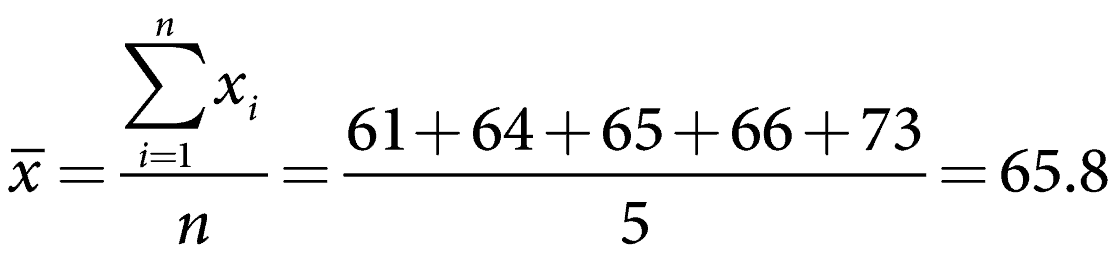

Often, products fail, and we don’t understand why! One of the reasons why such failures occur is not giving consideration for variation in load or stress levels. For example, potholes and speed breakers can create excessive stress on automobile suspensions; or larger number of clothes washed in a machine more often than the designer has considered; or a bus used in public transport would carry varying number of passengers! Designers often do not realize that the materials used in the product will also have variations! For example, wall thicknesses of castings will vary; or chemical composition of steel will vary from lot to lot! Thus, designers need to address the variations in usage patterns and variations in the materials used in the product as these can seriously affect reliability of systems! In my recently uploaded video, I have discussed how to predict reliability when load (stress) and strength of the part both vary and can be modelled using normal distribution. The video will also be very useful to those who wish to take ASQ Certified Reliability Engineer exam and all those who wish to learn the basics of reliability in design. This is the first video where the stress and strength can be modelled using normal distribution. In the next video related to this topic, I will explain reliability prediction using Monte Carlo Simulation.

[Read more…]