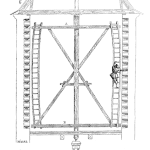

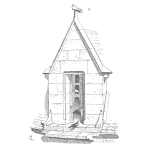

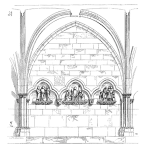

William Sutherland was a ship’s master carpenter in the late 1600s. Returning to shore, he became a foreman in the Portsmouth dockyard, then was promoted to be a senior manager at the Deptford yard. Sutherland wrote two books about naval architecture and ship construction. His 1717 book Britain’s Glory: or Ship-Building Unvail’d documented lifecycle maintenance in the Royal Navy.

[Read more…]