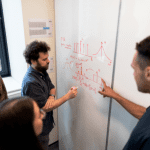

According to the International Labor Organization (ILO), there were 11 deaths every 100,000 workers in India in 2005. This number was two in the US and 0.01 in Japan. What is scary is that the number of fatalities may be significantly underestimated because of absence of a formal accident tracking system. I suspect the situation in other developing nations isn’t significantly different.

Why is the fatality rate in the industrial sectors in the developing nations so high?

[Read more…]