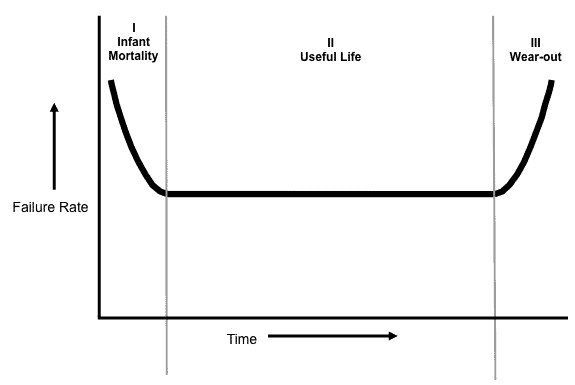

Confidence is used in reliability to give a probabilistic value to the likelihood that a taken measurement will represent a full population. It is determined by measuring a sample size and then using a selected statistical distribution table to translate to a likelihood. Emotional confidence is how one feels about making a decision based on known information at a specific point in time. Similar but different. But it is important to connect them. This is why. [Read more…]