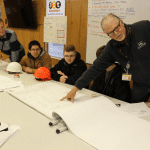

Leadership Connection Interview with George Parada

The Leadership Connection Host, Doug Plucknette, interviews reliability leader George Parada in Episode 2 of this series. George has spent his career working in the food and beverage industry and is currently the Global Asset Management & Ops Readiness Manager at Facebook.