Using the Critical Path to Guarantee a Successful Shutdown

Shutdown, Turnaround, Outage are all the same thing. An extended planned downtime event, in which a tremendous amount of resources are utilized to ensure the site will be able to achieve its business goals. Whether the shutdown involves overhauls, CAPEX or a combination, the successful completion of the shutdown depends heavily on the planning and execution of it.

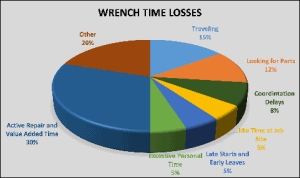

Shutdowns are resource intensive and often under compressed timelines. This unique situation requires a different approach to planning, scheduling and executing work, than the typically Maintenance Planning & Scheduling process. [Read more…]