In the push toward digital transformation, automated inspection, and AI-enabled quality systems, it’s easy to overlook the fundamentals that quietly hold everything together. Among them are two terms that are frequently confused, even by seasoned professionals: Calibration and Verification

These words live at the core of measurement assurance, and understanding the difference isn’t academic; it shapes risk decisions, audit outcomes, and ultimately, product quality and reliability.

What Is Calibration?

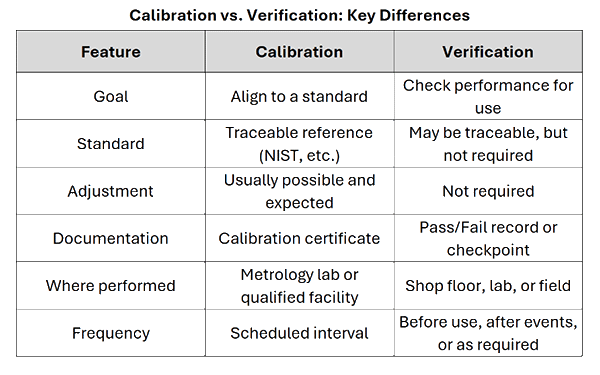

Calibration is the process of comparing a measurement device to a known, traceable standard and adjusting it if necessary, and its purpose is to maintain the accuracy and traceability of measurements over time.

Think of calibration as the alignment step that ensures the device’s readings match reality within specified limits.

The key elements of calibration include:

- Use a known reference standard traceable to a recognized authority.

- Quantify measurement error.

- Often includes adjust to bring readings back into tolerance.

- Generate a calibration certificate documenting results and uncertainty.

- Define intervals based on stability, risk, and historical performance.

As an example, digital micrometers are sent to a metrology lab. It is compared to gage blocks traceable to NIST. The technician finds it reads +0.0006″ at 2″, and then adjusts the device to within ±0.0002″. Results and uncertainty are recorded on the calibration certificate.

In reliability and quality, calibrated tools ensure you’re not making incorrect decisions about parts, processes, or capability.

What Is Verification?

Verification is the process of confirming that an instrument or measurement system meets requirements for its intended use without needing to adjust it.

Where calibration aligns, verification checks fitness for purpose.

The verification process confirms the instrument is working correctly before use and typically follows these steps:

- Compare to a reference standard.

- Determine whether the instrument performs within acceptable limits.

- No adjustment is required (though it may trigger calibration).

- Often performed at point of use.

For example, an operator checks a torque wrench against an in-house torque tester before the start of her shift. The wrench passes, and it simply continues in service.

Verification reduces the risk of measurement-induced failures, i.e. bad data leading to bad decisions.

Why the Distinction Matters

Confusing these two can introduce hidden risk into measurement systems, especially in:

- Gage R&R studies: A verified but uncalibrated gage can inflate variation.

- Process capability analysis: Bad data drives false conclusions about Cp/Cpk and yield.

- Audit defense: ISO 9001, IATF 16949, and aerospace standards expect clear evidence of calibration and point-of-use verification.

In short,

Calibration protects traceability and accuracy.

Verification protects day-to-day measurement confidence.

You need both.

In manufacturing and reliability engineering, data is currency. Measurements drive decisions, and decisions shape product performance, safety, and customer trust. Fancy dashboards, statistical tools, and AI models are only as good as the numbers behind them. Sometimes, going back to the basics is the most advanced thing we can do.

Ray Harkins is the General Manager of Lexington Technologies in Lexington, North Carolina. He earned his Master of Science from Rochester Institute of Technology and his Master of Business Administration from Youngstown State University. He also taught over 120,000 student quality-related skills such as Reliability Engineering Statistics, An Introduction to Reliability Engineering, Quality Engineering Statistics, An Introduction to Quality Engineering, Root Cause Analysis and the 8D Corrective Action Process, Process Capability Analysis, and Return on Investment Analysis for Manufacturing through the online learning platform, Udemy. He can be reached via LinkedIn at linkedin.com/in/ray-harkins or by email at the.mfg.acad@gmail.com.

Leave a Reply