Centrifugal Pump Life Extension – The Volute

What readers will learn from this article.

- Pump volute problems and fixes.

- Pump set-up and piping connection issues to get right.

- Process conditions that will cause problems.

- What to watch for with pump shaft designs.

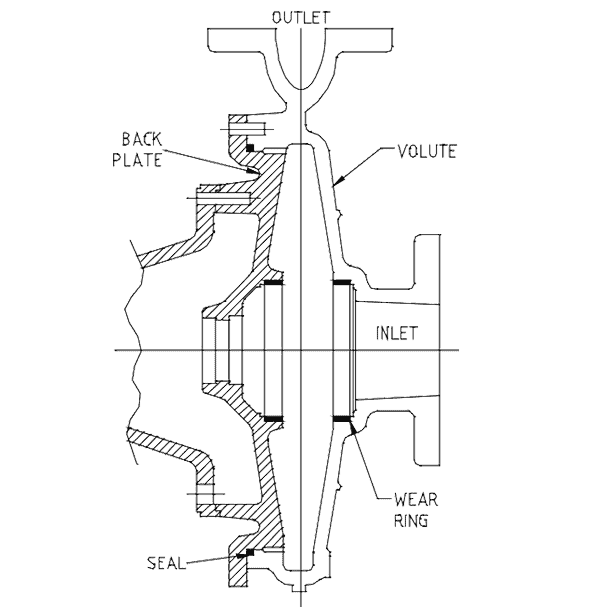

The volute contains the process media while supporting the inlet and outlet nozzles and the bearing housing. Typical failures are –

- Metal castings cracked through at nozzles and around the volute. Broken off hold-down bolt bosses.

- Plastic volutes cracked, bent and deformed; threads stripped.

- Slurry pump rubber volute liners cut-up or worn away.

- Plastic volute liners pierced by foreign objects.

- Containment shells on magdrive pumps cracked and scoured.

- Internal surfaces scoured deep by slurries and thick liquids.

- Leaks from flanges or the back plate on back-pull-out pumps.

- Casting cavities and inclusions in the metal from manufacture.

- Internal and external corrosion by the process media.

- Cavitation and gas inclusion pitting.

- Wear ring erosion and rubbing.

Cracking or warping usually mean one of the following.

- Severe pipe stress. The best advice I have had on the subject of pipe stress was from a Thompson Kelly and Lewis pump rep. This is what he does on all new installations – mount a dial gauge on the volute or base frame with the dial tip against the connecting pipe at the nozzle. Unmake the nozzle connection and let the pipe free. If the gauge indicates more than a 0.1- mm (0.005”) movement he gets the pipe cut off and rerun. If that is not done then he advises the owner of the pump that the warranty will be voided.

- Water hammer produces pressure surges and pipe vibration.

Water hammer usually means a fast operating valve(s) somewhere in the piping circuit. These need to be found and the opening/closing stroke times increased. - Thermally induced pressure from trapped liquid.

Liquids expand when heated. Unless thermal pressure is vented off, or the temperature is reduced, it will build until something breaks. One method to prevent thermally induced pressure build-up is to install pressure relief between the in-line valves.

Liner damage may be due to fair wear-and-tear. In this case if the liners do not give satisfactory life it becomes necessary to start testing alternate lining materials. In the end if the liner’s working life cannot be improved and maintenance and operating costs are unacceptably high then get rid of the pump and change to a different technology. If instead the liner damage is due to unwanted solids inclusion it becomes necessary to separate the solids out from the process liquid. Installing a straining filter with as large a mesh size as possible or settling the solids out in a tank and drawing the liquid off the top can do this.

Internal scouring can be due to the presence of particulate or from high local velocities. Scouring thins the volute wall and wears it through. Eddies, vortices and tracking can develop between the impeller and volute if the clearance is too large. Regular inspection of the volute internals will identify problem. Some pumps allow the clearance between the impeller and the volute to be adjusted. A hard coating system can be applied to the volute for protection.

Leaks pass gaskets can be due to poor gasket coverage on the sealing surface, wrong bolt torque-up practices, incorrect gasket material, pipe misalignment or corrosion of the sealing surface. If the leak is found early on then re-tensioning the bolts might stop it. If the leak is not detected it will damage the sealing surface and continually get worse. To fix such leaks the complete replacement of the sealing surface will be required.

Chemical corrosion by the process media can only be solved by proper selection of the materials in contact with the chemical. It is possible to line the volute with a chemically inert barrier coating and then machine the required clearances.

Cavitation is the creation of gas bubbles due to low pressures causing boiling. Cavitation pits would usually occur on the suction inlet nozzle walls. One solution is to find a way to increase the suction pressure. Gas inclusion is gas bubbles trapped in the process liquid. They can collapse as the spinning impeller causes the pressure to rise from suction to discharge pressure. Find ways to remove the gas bubbles before entering the pump.

Wear ring erosion and rubbing reduces the running clearance between the fixed wear ring on the volute and the rotating ring on the impeller. Once the gap gets larger the liquid from the high pressure discharge circulates back through the gap to the low-pressure suction and less liquid is draw through from the supply tank and pumping efficiency falls. The shaft on a pump is like a springboard at a swimming pool. Unless the shaft is sufficiently stiff and the impeller well balanced the spinning impeller will bounce up and down and the wear rings will clash. Inspection and measurement of the wear rings will pick-up problems. There are formulas that can be used to check a shaft and bearing arrangement will be stiff enough to reduce ‘spring-boarding’.

Mike Sondalini – Maintenance Engineer

If you found this interesting, you may like the ebook Centrifugal Pump Problems & Answers.

Leave a Reply