What you will learn from this article.

- How cyclones and hydrocyclones work.

- Where cyclones are used.

- Design features that affect cyclones.

- How to get long life from cyclones.

A tornado can lift cars from the ground and hurl them hundreds of meters away. Chickens and ducks can be hurled kilometers away. The story of fish falling from the sky is explained by the power of a tornado to lift materials kilometers into the sky. The spinning vortex of air separates and segregates heavy and light objects. The heavy objects drop out sooner and the light objects are carried further. Cyclone separators and hydrocyclones work the same way.

Design of Cyclone Separators

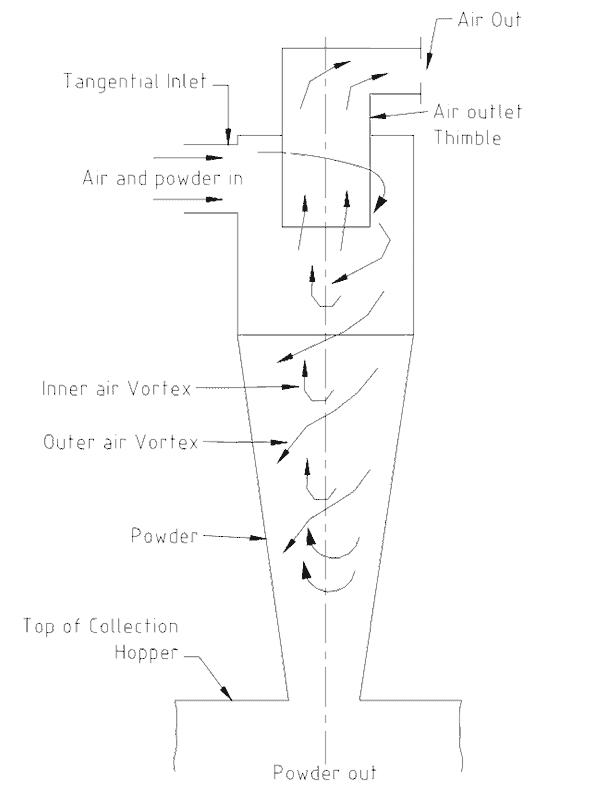

The most common type of cyclone separator is the tangential inlet, axial discharge style shown in Figure No. 1. The second often-used design is the axial inlet, axial discharge type which uses slanting vanes to start the air spinning. The tangential inlet cyclone covers a much larger range of throughput and particle sizes than the axial inlet design and is cheaper to make. Both work on the principle of using a spinning column of air to separate particles of different weights. A hydrocyclone spins a column of liquid instead of gas. Cyclones are used to separate liquids and solids from a gas stream. Hydrocyclones separate solids from liquids or one liquid from another of different density. The inlet stream enters the top chamber at high velocity and spins around the inside wall of the chamber. Any material above the weight that can be held up by the moving stream is flung out to the wall of the chamber and begins to slide down to the bottom outlet.

The stream then spirals down the cyclone top and enters into the conical bottom as more comes in from behind. Since the cone tapers inward, the available volume to take the full stream decreases. The speed of the stream increases to keep a constant mass flow through the cyclone. The stream velocity is higher and spinning faster as it moves down the cone. So fast in fact, that the centrifugal forces on the smaller particles remaining in the stream overcome the carrying velocity and are flung out to the wall. As the stream moves down the cone the particles being separated out become smaller and smaller.

Have you seen cigarette smoke sucked out of a moving car window? It is a natural law that a moving stream of air produces reduced pressure at right angles to its direction of motion. The ‘moving’ air at the open window is at a lower pressure than the air in the car and the smoke is drawn to the window. The same law applies in a cyclone. The stream spinning against the inside wall of the cyclone produces a low-pressure area at right angles to its motion. The low-pressure area develops in the middle of the cyclone and becomes a reverse spiraling column of fast moving low-pressure gas exiting the outlet nozzle in the top chamber.

Critical Shape and Flow Patterns

The critical factors affecting cyclone operation are sufficiently high gas stream velocity, particle agglomeration characteristics (tendency to join and stick together) and cyclone diameter-to-length ratios of the top cylinder and cone. By altering the size ratios of the cyclone sections it is possible to design cyclones that will remove (cut) particles above a specific size/weight proportion.

Configuration of a Cyclone in Use

A cyclone requires a high velocity, moving stream of gas to be consistently fed to it. A fan is used to push or suck the gas through the cyclone. The flow needs to be steady and not fluctuate otherwise the counter-moving vortexes within the cyclone cannot develop and be sustained.

The bottom outlet is required to be air tight so no air bleeds into the low-pressure central vortex. If air does leak through the bottom outlet the particles on the inside wall of the cyclone are re-entrained in the air steam and are sucked up the inside vortex and out the gas outlet nozzle. A rotary valve or an automated twin butterfly valve air-lock arrangement can be used on the bottom outlet. If a dustbin is installed on the bottom of the cyclone empty the bin regularly so the dust does not fill up and enter into the cyclone.

Cyclones can be run in series or in parallel. When in series they are often configured so that the first one takes out the big particles while the next takes out smaller particles. Series operation produces high-pressure drops and requires more powerful fans to force the stream through the system.

High particle velocities within the cyclone will wear away the walls. For aggressive materials the internal walls will require lining or use of a harder material than the particles. If rubber is selected check that the particle hardness and shape do not rip into the soft rubber. At times harder urethane plastics and even ceramic linings maybe required.

Mike Sondalini – Equipment Longevity Engineer

References: Muhammad E. Fayed & Lambert Otten, Handbook of Powder Science and Technology Chapter 15, 1997

Perry Robert H, Perry’s Chemical Engineer’s Handbook 1984, McGraw-Hill Book Co.

If you found this interesting, you may like the ebook Bulk Materials Handling Introduction.

Hi,

In the above design, is the discharge hopper also under vacuum? Can it be exposed to the atmosphere of will that create an updraft?

Thanks