The differential pressure transmitter (PT) is used to detect a head of pressure.

The sensing element is connected to the process by pipework and flexes in proportion to the pressure. The resulting distortion produces an electric signal that is amplified and converted to a value on a read-out.

Keywords: pressure sensor, strain gauge, tank level, process pressure, pressure difference.

A typical sensing element is a strain gauge of piezoelectric crystal (such as quartz, which produces a voltage across its opposite faces when under mechanical stress) that produces an electric signal proportionate to the pressure.

The process side of the sensor sees the pressure to be measured while the other side is connected to a reference pressure.

The reference pressure can be full vacuum, atmospheric pressure or another process pressure.

The PT can be used to calculate the flow rate through a pipe. By connecting it across an orifice plate in a pipeline the pressure difference across the orifice can be put into a formula and the flow calculated.

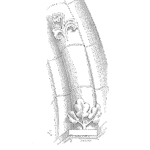

Pressure measurement accuracy ranges from +/- 0.2% to +/- 1% depending on the manufacturer’s design. Figure 1 shows a simplified cross-section of a style of pressure transmitter.

Keep a large pressure difference across the PT.

When only a small difference between pressures exist on either side of the transmitter it is possible for the error in the transmitter to make it appear there is sufficient pressure when in fact the pressure difference is reversed.

Chemical Compatibility

Many process chemicals will destroy the internals of a PT.

To prevent contact with such chemicals a flexible diaphragm process seal is used to connect to the process and the PT is mounted on the other side. Select diaphragm materials that give many years of corrosion free service.

Protect against pitting and stress corrosion cracking in particular.

Temperature Compensation

Differential PT’s may not be temperature compensating.

As the outside temperature changes, the oil fill expands or contracts. The change in volume causes the pressure inside the transmitter to also change.

This makes the sensor distort and give a false pressure reading. In such cases protect the transmitter from temperature fluctuations.

Diaphragm cleanliness

The sensing diaphragm on which the liquid pressure acts must be kept clean.

Sediment build- up will stop the diaphragm from flexing freely and will produce false readings. Products that crystallize at cooler temperatures need special attention.

Keep the liquid temperature at the diaphragm surface hot enough to prevent crystals forming in the cooler crevice between the diaphragm and transmitter body or insulate the body to reduce the heat loss through the walls.

Mike Sondalini – Maintenance Engineer

Leave a Reply