We all want high productivity – maximum output for the least input, the most blast for our buck! We know that high payback will entail a level of risk, but again, we want to minimize our downside risks and maximize the opportunities that may be available to us. We need practical ways to achieve this. Good Capital Asset Management™ will deliver that – how? Well, here’s a simplified scientific explanation of how that works.

Engineers are familiar with the concept of “entropy” and the laws of thermodynamics. The second law of thermodynamics states that total entropy of an isolated system always increases over time. It can remain constant in ideal cases where the system is at a steady state or undergoing a reversible process. So what does that mean?

Entropy (usually represented by the symbol “S”) is a measure of microscopic configuration making up a thermodynamic system – in simpler (practical) terms it provides a measure of randomness or chaos in a system.

The second law tells us that S (randomness or chaos) will increase unless we can keep our system in a steady state or subject it to some form of reversible process. Consider a factory, process plant, utility or fleet that we are maintaining. That factory… is our “system”. If we do nothing but use it (which is what the operations people will want to do), then entropy will increase. Chaos and randomness will increase. This presents itself to us as system deterioration – wear, random failures, fatigue, erosion, etc.

We can stop this process if our system can be kept in a steady state, but that is more or less impossible given natural degradation processes that are inherent in virtually any system we devise. We can however apply a “reversible process” – maintenance to restore the system’s state. We apply energy (maintenance) to reduce the system’s entropy (chaos).

Because maintenance has a cost and takes time, we want to apply as little of it as possible. If we do that we save money and have more time available for productive use of our system. What activities will help us to achieve this?

There are three main activities:

- Design the system so it is inherently reliable (i.e.: degradation is slow) and maintainable (i.e.: quick to restore after it has degraded),

- Maintain the system properly (i.e.: addressing specific degradation processes and no others), and

- Operate the system as steadily as possible and within its capability so it degrades at the slowest possible rate (i.e.: don’t overload, shock or abuse the system).

From the thermodynamic perspective each of those is achieving a goal (respectively):

- The steady state system has a low level of entropy,

- We apply the right amount of energy to restore entropy increases back to original state quickly, and

- We operate the system in as close to steady state as we can to slow entropy growth.

Financially the implications are:

- We invest in an inherently reliable and maintainable design which often costs a bit more up-front,

- We spend money on the right kind of maintenance, focused on reliability, not on cost reduction leading ultimately to lower costs overall, and

- We end up with a high level of predictable, steady output and low variability leading to stable revenue flows.

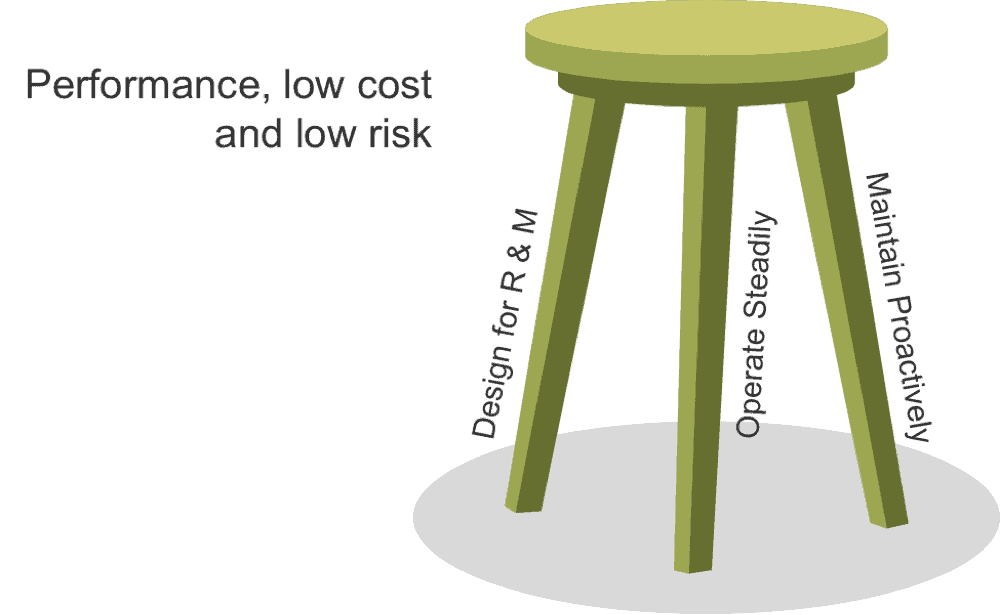

Success with your system means high performance at low cost and low levels of risk to that performance. There are three keys to success, much like 3 legs on a stool: inherent reliability and maintainability due to design, sustaining the performance through the right maintenance and avoiding accelerated degradation through proper operation.

Just like any 3-legged stool the system is stable so long as the three legs remain intact.

In part 2 I’ll explain the economics of this simple model.

very well explained! i loved it! keep rocking