Why Doesn’t Reliability Process Change the Product?

Abstract

Adam and Fred discussing how to change the way processes are used to implement reliability tools so the results drive product change.

ᐅ Play Episode

Your Reliability Engineering Professional Development Site

by Adam Bahret Leave a Comment

Adam and Fred discussing how to change the way processes are used to implement reliability tools so the results drive product change.

ᐅ Play Episode

by James Kovacevic Leave a Comment

This episode is centered upon the failure mechanism that reliability engineers have to deal with in everyday work. Before we understand what a failure mechanism is, it is very important to know what is called a failure. A failure is a technically relative term that is used when the results are below the expectations. Now different people have different definitions of failure based on their own performance scales. The failure depends on the criteria of performance that you have set for a particular machine and when the machine falls short of generating that specific output, you call it a failure.

ᐅ Play Episode

by Carl S. Carlson Leave a Comment

Carl and Fred discussing the big picture topic of reliability in our lives, and how our experiences can affect the application of reliability.

ᐅ Play Episode

by James Kovacevic Leave a Comment

In this episode, the guest Fred Schenkelberg explains what is a good consultant? Whenever comes the question of performance in an organization—performance of assets—there is always a consultant involved who is helping you make your organization better at what you do. So what is a consultant? The consultants are mainly categorized into three major types. There are contractors who help you set things in motion or strategists who make strategic decisions for you. Then there are facilitators or internal ones who you hire for specific projects so that they can assist you just like an extra set of hands. The last ones are trusted advisors who help you every step of the way and if they are truly capable—which they usually are—with experience and expertise, they can really make a difference with the knowledge and insights that they have.

ᐅ Play Episode

Kirk and Fred discussing the differences found between what is considered a “Quality” department issue, and what is a “Reliability” department issue.

ᐅ Play Episode

by James Kovacevic Leave a Comment

This episode is about the reliability improvement journey of Jason Tranter who is currently the managing director—also the founder and owner—of Mobius Institute. He started his journey when vibration analysis was just in the early phase and organizations were keen to work on condition-based maintenance to have good productivity and improved availability. Reliability in the present times, depends heavily on the availability of the equipment and vibration analysis helps greatly in this endeavor to make your assets more dependable which ultimately improves reliability techniques of an organization. You want the systems to operate when you need them to operate and you make sure that they do so by improving reliability at different levels. This results in increased uptime, quality products leading to time and cost saving. The concept of reliability changes depending on the organizations but the main goal should always be to help the organizations achieve their objectives by taking measurements of running of equipment whenever needed.

ᐅ Play Episode

by James Kovacevic Leave a Comment

In this episode, the guests, James Reyes-Picknell and Jesus Sifonte talk about the RCM Reengineered that they have also explained in their book—to be launched on 20th April— with a lot of practical approaches as well. The RCM Reengineered is based on the original RCM technique to avoid and manage failures occurring during the asset management process, but it optimizes a lot of factors with a broad range of criticality measures and problems that come along with it. The RCM has been around for a long time and was developed to handle the safety issues in flights but RCM Reengineered focuses on the failures that are science-based and then it provides you with the exact solutions that must be implemented to achieve long-term and sustainable reliability operation depending upon the type of the industry.

ᐅ Play Episode

by James Kovacevic Leave a Comment

In today’s episode, the guest Fred Schenkelberg explains the Monte Carlo simulation in a fair amount of detail. Before you get in the depth of how the tool works, you need to understand what basically this method is. The Monte Carlo simulation has been around since World War 2 and it is a mathematical technique that works based on probability functions, random variables, and the distribution of statistical data. The main concept of it to give the decision maker the most obvious choices while facing any risks to get the best out of every possible outcome. The tool serves the purpose for getting a better insight of the consequences relative to each choice the person making decisions has to make. When you’re looking for the reliability of your assets and checking the integrity of your different maintenance programs, it is a really powerful tool.

ᐅ Play Episode

by James Kovacevic Leave a Comment

In this episode, the guest Paul Crocker tells his inspiring Maintenance and Reliability Engineering journey. He is an Uptime award holder in the innovative use of photography for maintenance in the Kansas City. He has been taking pictures of every equipment in the workshops, in the field, and everywhere he can. These pictures have worked like a living notebook for him—just a much better to look at, kind of. He suggests it to his coworkers and trains people to do the same as pictures of issues that an engineer faces in routine, failure data and equipment information can be pretty useful sometimes.

ᐅ Play Episode

by James Kovacevic Leave a Comment

This episode of the weekly podcast is focused on the 2016 SMRP conference and is described in detail by one of the Board members of the SMRP itself, the education director Christopher Mears. Society for Maintenance and Reliability Professionals is a shared group where you get many opportunities to learn, experience, and improve your working skills for your own and your organization’s benefit. They have an annual event in October called the SMRP conference where professionals from around gather and get a know-how about the best practices that many good quality CMRPs use in different industries. It is shared event in which many companies exhibit in workshops which technologies they are using right now. What have they come across while dealing with the reliability improvements and what are they up to—not the specific details like confidential designs, documents, and charts. But kind of keynotes that are food for thought if you are keen to make yourself better in the race of reliability professionals. Apart from this yearly event, you can find the webinars of SMRP members on the official site along with the presentations of different professionals that are working in the leading organizations of the field. The exhibitors of this society are very successful at what they do and if you want to start your reliability engineering journey—doesn’t matter if you’re a student, earlier in the career, or an experienced professional—there’s plenty for you to do in the workshops along with a chance to see the best facilities of the city in which the conferences are held.

ᐅ Play Episode

Kirk and Fred discussing the value of reliability in consumer electronics in comparison to the rapid technological improvements.

ᐅ Play Episode

by James Kovacevic Leave a Comment

In this episode, the guest Dan Anderson explains the role of Reliability Assessments in the organizations. Whenever an organization starts its journey towards the reliability excellence, it has to start by considering some things. One of the very first steps is to create awareness among all the employees. The workforce needs to understand and learn about the goals and objectives of the organization. Now once the employees have sufficient understanding, they should be ready to cooperate in any way organization needs them for a better and long term reliability plan.

ᐅ Play Episode

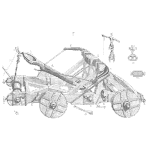

This episode is about designing for reliability. It has been proven over time that the best inventions are designed properly after planning them and before implementation — even in the earlier times people used to draw things before they actually made them. After you have done an analysis of the equipment, there is not even close to good probability to make that product completely reliable. That is why a good design should be made before developing anything for which companies hire professional designers and good ones have their own designing teams too.

ᐅ Play Episode

James and Fred discussing the necessary connection of reliability and maintenance to business objectives.

ᐅ Play Episode

This episode of the weekly podcast discusses the basics of Weibull analysis and distribution technique. By using it you can precisely calculate the probability of failures through a statistical analysis of the failure data. As it is a statistical way of calculating the failure rate and getting an idea about the downtime and life of the equipment, it needs data.

ᐅ Play Episode