Mag-flow meters are used to measure the flow velocity of conductive liquids. In a magnetic flow meter an electromagnet placed either side of the bore creates a magnetic field when the power is turned on. As the conducting liquid flows through the magnetic field a voltage is developed across the liquid. Insulated electrodes flush mounted in the wall of the meter detect the voltage. The magnitude of the induced voltage is proportional to the liquid velocity, the length of the meter and the strength of the magnetic field.

Keywords: electric current, isolation flanges, calibration.

In a magnetic flow meter an electromagnet placed either side of the bore creates a magnetic field when the power is turned on. As the conducting liquid flows through the magnetic field a voltage is developed across the liquid. Insulated electrodes flush mounted in the wall of the meter detect the voltage. The magnitude of the induced voltage is proportional to the liquid velocity, the length of the meter and the strength of the magnetic field.

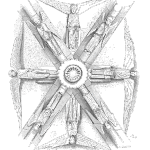

The detected voltage is converted to a flow rate by the electronics and software within the instrument and displayed as readout on a control panel. Figure 1 shows a cross-section through a typical magflow meter.

The inside bore of a magflow meter can be lined with a variety of nonconductive materials that allow the meter to be used with aggressive chemicals and slurries. The electrodes can also be supplied in different metals compatible with the chemical and process to be measured.

Magflow meters have the advantage of being a full bore device with no projections into the flow path. Because of this they are useful for measuring slurries or in situations where pressure drops need to be minimised.

The meter can be mounted in the vertical or the horizontal. For a magflow meter to work correctly and with confidence it must always be full of only liquid. It cannot recognise the presence of bubbles carried in the liquid or gas cavities on top of the liquid and will give false flow rates if they are present. If necessary modify the pipe work to produce full bore flow in the meter.

Problems with magflow meter accuracy can occur if the electrodes transmitting the small voltages created in the liquid become coated with process contaminants. Long signal transmission cable runs or outside electrical interference affecting cables can produce false readings.

Be careful with regards the stated calibration accuracy as tests and calibration setting is usually done with water. When the meter is used on non-water fluids wide errors are possible. It was found that a magflow meter of stated 0.2% accuracy was 2.5% accurate on caustic soda solution. When the issue was brought up with the supplier they were astounded in the discrepancy.

An especially critical requirement is correct earthing. The meter cannot differentiate between voltage from the liquid flow or voltage from other sources. To insure the meter is only reading voltage from the liquid it is necessary keep the meter body in electrical contact with the liquid.

In plastic pipes this is done by the use of graphite gaskets between the body and flanges or by putting an earthing ring of metal compatible with the chemical and connecting it to the meter body. In metal pipes the electrical contact is maintained by connecting a metal tag on the meter body to a metal tag on the metal flanges either side.

Mike Sondalini – Maintenance Engineer

Leave a Reply