Properly designed o-ring grooves and properly installed o-rings stop the passage of pressurised liquids or gasses. Flexibility while being deformed under pressure is their greatest sealing advantage. O-Ring Design and Materials O-rings are made of elastomeric materials such as rubbers and plastics. They deform under pressure and then return back to their original shape once the pressure is removed. They also accept the movement of mirror-finish shafts while deformed by pressure. Usually they are shaped like a rubber elastic band of round cross section, but they can have rectangular, trapezoid and even ‘+’ shapes depending on the application. The material, internal diameter (ID) and cross section diameter specify o-rings of round cross section.

O-ring Groove

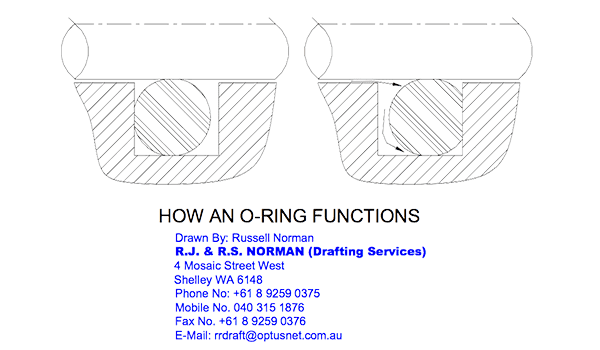

An o-ring is fitted inside an o-ring groove to locate and shape them ready for the application of pressure. The dimensions of the groove can be found in design reference books for the size of o-ring concerned. A most important requirement for the groove is that its depth produces a diametral squeeze on the o-ring to compress it and develop flat sealing surfaces against the top and bottom of the groove. There should be 40 to 45% of the original o-ring cross sectional area as a sealing surface at ZERO pressure. The groove needs to be wide enough to accept the material that is squeezed sideways and allow for slight o-ring movement when the pressure is applied. If the operating temperature is elevated the groove must also be wide enough to permit thermal growth of the elastomeric material.

Figure 1 shows a properly compressed o-ring both with and without the application of pressure. Note the flat sealing surface top and bottom caused by the squeeze of the groove components. Pressure pushes the o-ring up against the wall of the groove and it is deformed to produce three sealing faces. The more the pressure is applied the better the seal developed.

Limitations of Use

The rubber and plastic compounds from which o-rings are made have limitations. Rubbers and plastic have limits on their operating temperature range. Also the elastomeric compound of the o-ring may not be compatible with certain chemicals. These issues must be checked. The properties of the elastomeric can be found from the o-ring supplier.

Installing O-rings

O-rings are soft and easily damaged. Once nicked, cut or abraded they will never seal properly and must be replaced. Remove o- rings with a rounded wooden or plastic spatula. Never use sharp steel , metal wire or screw drivers to remove them as these quickly and easily cut into the elastomeric (and your hand) and damage it.

The 0-ring and groove must be free of dirt and debris when installed. Any foreign material squeezed into the groove will lead to leakage. Clean o-rings with a lint free cloth by holding the cloth in hand and gently pulling the o-ring through around its entire loop several times. Inspect it under good light to confirm it is in good condition. Clean the recessed groove out with a lint free cloth or Q- tips (cotton tips). Remove all old lubricant, oil and dirt.

To mount the o-ring into the groove may require that it be stretched over part of the component. Warm the o-ring to soften it. Any edges must be chamfered and deburred. Depending on the o-ring material a lubricant can be lightly applied to the o-ring to help it slide. Check with the o-ring supplier as to the appropriate lubricant for the o-ring.

Mike Sondalini – Maintenance Engineer

If you found this interesting, you may like the ebook Centrifugal Pump Problems & Answers.

Leave a Reply