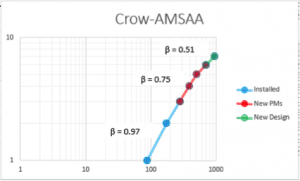

Using the right plot enables your team to know what is working or need improvement.

Part 4 of 7

Your facility has data and maybe too much data. Using simple plotting may be the key to unlocking how well your maintenance program is performing.

Building on the concept of reliability growth modeling James Kovacevic described a convenient way to quickly visualize your repairable system failure data is with a mean cumulative function (MCF) plot. [Read more…]