Have you ever wondered how RCM principles emerged? They were born from a hard-fought lesson in the mid 1960s by the commercial airline industry. Watch as I explain from 25,000 feet! [Read more…]

Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Nancy Regan Leave a Comment

Have you ever wondered how RCM principles emerged? They were born from a hard-fought lesson in the mid 1960s by the commercial airline industry. Watch as I explain from 25,000 feet! [Read more…]

by George Williams Leave a Comment

So where should the planner focus to be effective? This clip shows where to focus your energy to improve your overall planning effectiveness. [Read more…]

by Nancy Regan Leave a Comment

Join me and Elvis Presley in a game of “Reliability Centered Maintenance, True or False.” In front of the iconic “Welcome to Las Vegas” sign, we explore: 1) What RCM can yield; 2) What assets you can apply RCM to; and 3) Whether or not you need comprehensive failure data to do RCM. [Read more…]

by George Williams Leave a Comment

We discuss what traits make successful reliability journeys happen. This is part 1 of 2. [Read more…]

by Bryan Christiansen Leave a Comment

As more and more organizations seek to improve their maintenance, many are shifting from the reactive ‘repair-focused’ maintenance models to more proactive ‘reliability-focused’ maintenance which includes things like tracking, identifying, and eliminating failure, maintenance planning and scheduling, reduced downtime, reduced costs, continuous improvement, and similar.

by James Kovacevic Leave a Comment

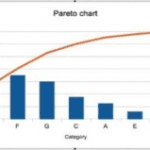

There is limited time, money or resources in every maintenance department. Sometimes you have 2 of the 3, sometimes just 1. So how do you prioritize the items or issues that will have the biggest impact on your facility? There is a simple, yet vital principle that can be used in your facility to determine which issues to focus on. This principle started in a garden in Italy while studying peas… This principle which started with an observation of peas can have an important impact on your operation.

by Nancy Regan Leave a Comment

Join me in a game of “Reliability Centered Maintenance, True or False” with some very interesting characters on the Las Vegas strip including: Vegas showgirls, Chewbacca, Darth Vader, Batman, and Mickey Mouse! [Read more…]

by George Williams Leave a Comment

We discuss justifying the maintenance planner position by demonstrating the expected efficiency gain of the maintenance staff through proper planning and scheduling.

by Doug Plucknette Leave a Comment

RCM Training should always reinforce the importance of ensuring the inherent designed reliability of the asset or system that is being analyzed. It is primarily this function of the RCM process that people fail to fully understand. The importance of properly conveying this message is what most often differentiates successful Reliability Centered Maintenance efforts from those who dabble and fail.

Reliability Centered Maintenance Training should always include a case study that allows the participants to identify failure modes that result in the team making task decisions in each of the following Consequence Categories: Hidden Failure Consequences, Health Safety and Environmental Consequences, Operational Consequences and Non-Operational Consequences.

RCM Training should always include real-life facilitation in a team format. It’s extremely important for those learning the process to understand the detail required to properly assess failure modes, failure effects and tasks.

by James Kovacevic Leave a Comment

It is well known that maintenance planning & scheduling can deliver significant improvements in the efficiency and effectiveness of the maintenance department. Maintenance planning & scheduling seems simple enough, plan the work and schedule it to be done at the most opportune time. However, why is it that the organization seem to struggle with realizing the benefits of maintenance planning & scheduling? In my experience, I have seen organizations that focus on the scheduling portion of work management, while not fully planning the work. Doc Palmer (an authority on Maintenance Planning & Scheduling) has said that you cannot schedule without proper planning. So how is it that they are scheduling work without knowing what needs to be done and what materials are required?

by George Williams Leave a Comment

Lets look at the goal of planning and the two major areas of focus to increase efficiency of the maintenance staff. [Read more…]

by Nancy Regan Leave a Comment

I often hear people say that RCM is used to reduce Proactive Maintenance. I say, “it depends!” Watch as I explain… [Read more…]

by Nancy Regan Leave a Comment

This is one of the biggest reasons for one of the biggest misconceptions of the RCM process. If you’ve done RCM and it took you way too long, this may be the reason… [Read more…]

by George Williams Leave a Comment

Predictive Maintenance, Condition Monitoring, and Condition Based Maintenance have not been clearly defined and we are looking to begin a dialogue to create a standard definition for these terms. Join us as we begin our discussion. [Read more…]

by James Kovacevic Leave a Comment

I recently had the pleasure to interview Doug Stangier, co-author of Preventive Maintenance Made Simple. This is another excellent book in the Made Simple series, published by ReliabilityWeb. During the interview, Doug not only provides insights into his book but also into what world class Preventive Maintenance looks like. Anyone new to maintenance and reliability, or seasoned experts can benefit from this great book. Without further delay, here is the interview with Doug.

I recently had the pleasure to interview Doug Stangier, co-author of Preventive Maintenance Made Simple. This is another excellent book in the Made Simple series, published by ReliabilityWeb. During the interview, Doug not only provides insights into his book but also into what world class Preventive Maintenance looks like. Anyone new to maintenance and reliability, or seasoned experts can benefit from this great book. Without further delay, here is the interview with Doug.