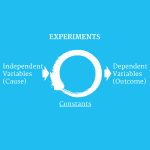

With all the complaints you hear about products rebooting and software crashing, do companies really practice Software Reliability? In fact, there are some companies that do, but they are mostly in the industries that require products to have high availability, such as telecom, defense, and space, or safety-averse industries, such as medical and industrial plant operation. Most other industries don’t pay as much attention to it. The best method to increase Software Reliability without significant increases to schedules or budgets is to use a Software Design for Reliability (SDFR) approach. These are the key steps. [Read more…]