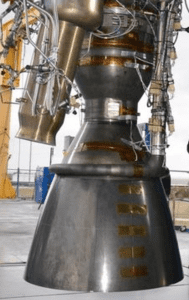

I don’t know if you recall a post from my blog, “HALT Testing is Not Always In a Chamber”, that discussed what I consider to be the first documented HALT test. Well I just found a video of the design solution in action and it is super cool. I discussed how during  the development of the F1 rocket motor, for the Apollo space program, they solved a design issue with a HALT technique, although they didn’t call it HALT at the time. The issue they were attempting to solve was the thrust nozzles fracturing due to oscillating vibration. [Read more…]

the development of the F1 rocket motor, for the Apollo space program, they solved a design issue with a HALT technique, although they didn’t call it HALT at the time. The issue they were attempting to solve was the thrust nozzles fracturing due to oscillating vibration. [Read more…]