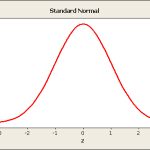

Telematics data presents the opportunity to characterize the vehicle lifetime usage. This information is used to validate development and testing targets. Because there can be bad or missing data, it needs to be reviewed prior to analysis to have confidence in the analysis. [Read more…]