Requirements for the typical company have few guidelines. This video gives an outline for what we have experience in industry and in our consulting experiences. It is essential for success. We can help you get there. [Read more…]

Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of articles by:

by Perry Parendo Leave a Comment

Requirements for the typical company have few guidelines. This video gives an outline for what we have experience in industry and in our consulting experiences. It is essential for success. We can help you get there. [Read more…]

by Carl S. Carlson Leave a Comment

Once you have identified the scope of the FMEA project, made the scope visible, it is time identify the FMEA team members. This article discusses the composition of the FMEA team, including why each member is needed, and the underlying reason for a cross-functional team.

“Alone we can do so little; together we can do so much.” Helen Keller

by Perry Parendo Leave a Comment

In sports, people talk about a go to guy or a go to play. What about in business or new product development? Where do you go during critical times? We find companies calling us to resolve those items. [Read more…]

When it is necessary to check 100% of parts for one or more characteristic?

There are situations where 100% of manufactured parts are checked. These include visual inspection, measurements of a part characteristic, and a reaction to low process capability. These may be accomplished manually or an automated process.

[Read more…]

by Perry Parendo Leave a Comment

What people need are practical business solutions. They do not need science projects – or efforts only for the sake of learning. [Read more…]

by Carl S. Carlson Leave a Comment

FMEA teams should agree to the ground rules that guide the analysis and the underlying assumptions that impact the entire FMEA. Failure to do so will add complexity and confusion to the resulting FMEA, and waste people’s time. Don’t miss this important step in FMEA preparation.

“Your assumptions are your windows on the world. Scrub them off every once in a while, or the light won’t come in.” Isaac Asimov

by Perry Parendo Leave a Comment

In sports, the mantra of “Respect all but fear none” is used by many coaches. This same philosophy is appropriate for New Product Development. Respect the design or process – nothing is simple. Yet, do not fear new things. A healthy respect for trying new things. This is how we coach and how we consult! [Read more…]

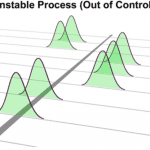

Many companies use SPC to control their manufacturing and assembly processes. Other companies use 100% inspection and some companies do nothing. How can one choose between these three alternatives?

To make a rational choice, some questions need to be answered.

by Perry Parendo Leave a Comment

We provide business solutions. How can we prove it? This video provides the basis for our experiences with results. [Read more…]

by Perry Parendo Leave a Comment

Often times DOE is considered a manufacturing tool. However, it can be used upstream during R&D and Operational Qualification (OQ) activities. There is much more leverage in this situation. A case study is provided from a client organization to bring the principles to life. This video is the slides and audio recording of the presentation at MDM Minneapolis, October 28, 2013. [Read more…]

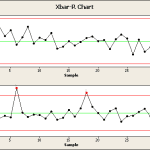

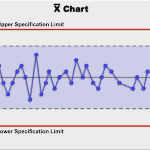

In my prior article, the assumptions behind SPC were discussed in detail except for the analysis. There are two types data that may be analyzed, Counts and Measurement variables. This article focuses on normally distributed measurement variables, and the construction and usage of $-\bar{X}-$ and R charts.

[Read more…]

by Perry Parendo Leave a Comment

We are often hearing about the shortage of skilled workers. Why is this? What can you do to address it? We believe there are a few reasons for it and we can help you overcome them. This can help you achieve a cost effective competitive advantage. [Read more…]

by Perry Parendo Leave a Comment

There are many benefits from acquiring our services. But what if you do not bring us in? This anti-case study describes a situation where they wanted to wait. The impacts came from discussions with company employees after the changes. Can you really afford to wait? [Read more…]

by Carl S. Carlson Leave a Comment

Before commencing with the FMEA meetings, it is essential to visibly show the nature and scope of the analysis. This article discusses different ways FMEA scope can be made visible, and why this is a necessary step.

“The soul cannot think without a picture” – Aristotle

by Dennis Craggs Leave a Comment

Statistical Process Controls (SPC) is a suite of methods that can be employed to control a manufacturing or assembly process. It has a wide range of potential applications ranging from consumer products to defense. It can be employed at the lowest element of component manufacturing or an assembly operation.

This article discusses the assumptions necessary to understand SPC.