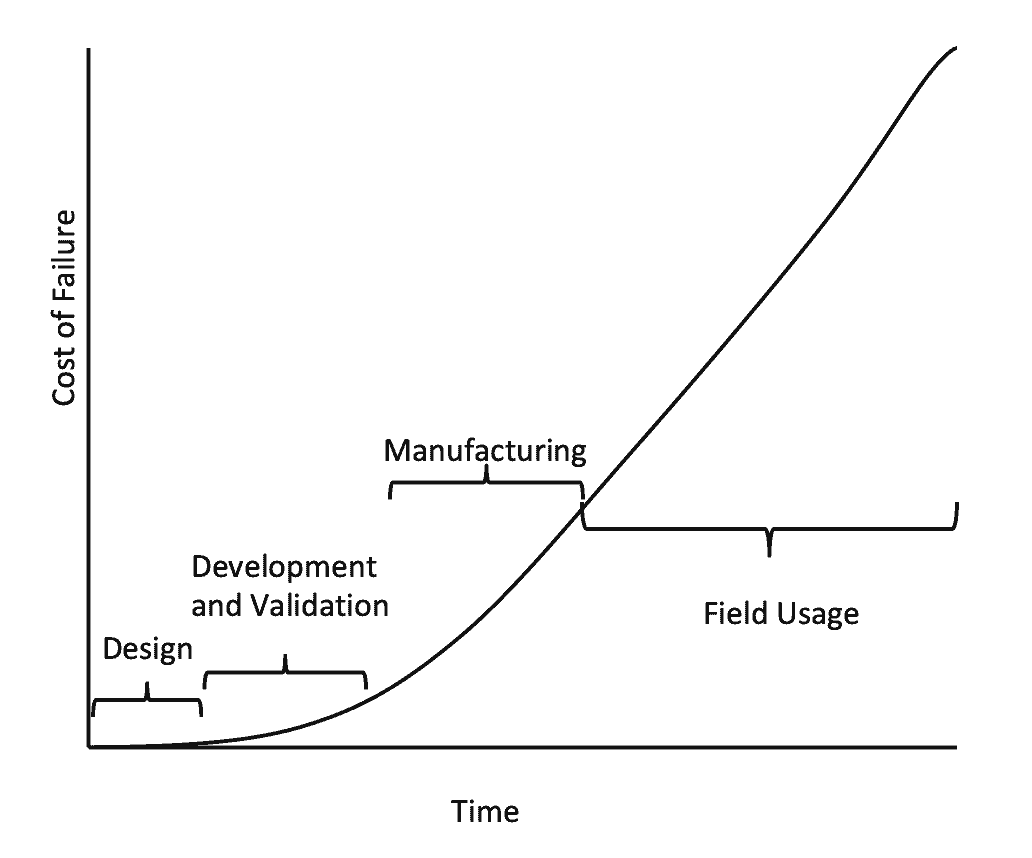

Many times, new equipment does not move smoothly onto the production floor. Eventually, operations will say “just get it out here.” Using our methodology, we have helped companies be in a position where they are telling us to wait to install it! When you can understand the equipment up front, it makes a huge impact. How do you fit on the spectrum? [Read more…]