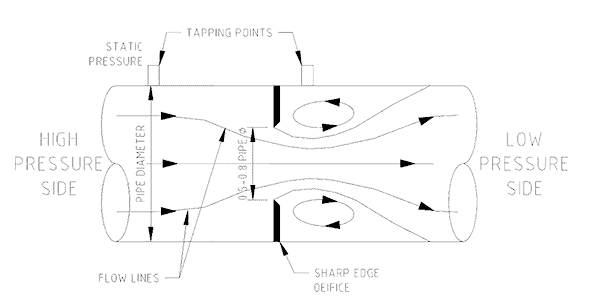

Orifice plate meter flow measurement. An orifice meter is a circular piece of metal plate placed between flanges in a pipe. In it is a square-edged round hole machined 0.5 to 0.8 pipe diameter in size. Pressure tapping points are placed either side of the plate at specified distances. The orifice causes a flow restriction and produces a pressure drop from one side of the hole to the other. The amount of pressure difference is proportional to the flow of fluid through the hole. The flow is calculated from the pressure difference and flow areas using accurate mathematical formulas.

Keywords: differential, static pressure

Effect of a restriction on fluid flow

When an object is put in the way of a flowing fluid (gas or liquid) in a pipe its presence obstructs the passage of the fluid. The fluid is forced to go around it. The flow diversion requires energy to power the motion and it is supplied from the fluid by its pressure falling as it squeezes past.

The smaller the hole, the less that can get through it, and the greater the back-pressure in the pipe. That is how a faucet (a tap) controls the flow of water into a drink cup when it is opened. Just cracking the tap open produces a trickle. The high back-pressure in the pipe forces a small amount of water out of the tiny opening. As the tap is opened further, the hole gets bigger and the flow increases. The back-pressure in the pipe falls as the restriction is removed.

By knowing the size of the hole and the pressure difference from one side to the other it is possible to calculate the flow through the hole. An orifice plate flow meter uses the differential pressure principle to determine the flow. Figure No. 1 shows a cross-section view of an orifice meter with its pressure tapping points and stylised flow lines.

Static Pressure and Velocity Pressure

The pressure in a pipe of still fluid and the pressure in the same pipe with the fluid now moving are different. If a pressure gauge were mounted on the pipe it would read a higher pressure when the fluid was still than when it was flowing through the pipe. When a fluid is in motion the static pressure drops and the velocity pressure rises.

An example of static pressure is the pressure of the air in a room with the windows slightly open while outside there is a howling gale. If you go into the gale you would feel the pressure of the wind on you. That pressure is the velocity pressure of the moving wind. At the same time you would experience the static air pressure acting on you. On the windward side you would experience the static pressure plus the velocity pressure. Behind you there would only be static pressure (less a small amount of vacuum pressure). The static pressure is all around you, whereas the velocity pressure is only in the direction of the wind.

The same situation develops in a pipe full of fluid. Where the static pressure is high, velocities are low and where velocities are high static pressure is low (Recall the change in back-pressure in the kitchen pipes as the tap is closed and opened).

Measuring pressure across the orifice

In order to read only static pressure in a pipe the tapping hole must not be exposed to the velocity component of the flow. Usually a pressure gauge is mounted in a hole drilled through the wall, square to the wall. At the inside wall of a pipe the velocity is zero and only static pressure is present.

An orifice plate flow meter uses static tapping points located at either side of the orifice. By convention the upstream static tapping is one pipe diameter up from the orifice and the downstream tapping is half a pipe diameter from the orifice at the location of the ‘vena contracta’ where the flow lines are most narrow.

The pressure difference between the two points is proportional to the flow and once the pressure difference is known it is put into an equation to find the velocity. From the flow velocity and cross-sectional areas of pipe and orifice, the volume of product flowing can be calculated.

Limitations of orifice plate meters

The accuracy of an orifice plate flow meter depends on the square edged remaining round and sharp. Wear or damage will produce errors in the pressure reading. It is also necessary to insure that no partial blockages occur upstream of the orifice that produce changes to the flow profile and pressure gradient. Blockages can occur in the sensing lines from the orifice to the transmitter or pressure gauge. The position at which the meters are located should be where the flow pattern in the pipe is straight and no turbulence exists.

Mike Sondalini – Equipment Longevity Engineer

Reference: Elementary Fluid Mechanics, Fifth edition , J K Vennard, R L Street, John Wiley & Sons.

If you found this interesting, you may like the ebook Centrifugal Pump Problems & Answers.

Leave a Reply