Failure data and the CMMS with John Reeve

In today’s episode, the guest is John Reeve and the agenda of discussion is failure data and CMMS. As everyone knows that to maintain and solve issues with the equipment you need to get all the basic data or information available. Computerized maintenance management system helps greatly in this task but first of all, you have to know exactly what kind of data are you looking for and what it means. Now failure data can be anything related to your asset that is the foundation data or then transactional data comes which includes the processing data related to the asset such as the actual cost. Now, next thing to understand is the failure mode which consists of the failed component, component problem and cause code. Once you have this failure data, it becomes very easy to run the basic failure analysis which is necessary at certain levels.

In today’s episode, the guest is John Reeve and the agenda of discussion is failure data and CMMS. As everyone knows that to maintain and solve issues with the equipment you need to get all the basic data or information available. Computerized maintenance management system helps greatly in this task but first of all, you have to know exactly what kind of data are you looking for and what it means. Now failure data can be anything related to your asset that is the foundation data or then transactional data comes which includes the processing data related to the asset such as the actual cost. Now, next thing to understand is the failure mode which consists of the failed component, component problem and cause code. Once you have this failure data, it becomes very easy to run the basic failure analysis which is necessary at certain levels.

Then to make the process smooth and reliable, you need to check the reports on a consistent basis, train your staff and make improvements. Then the configuration of your CMMS is the next step but you need to make sure that it will capture all the validated fields of the failure mode which is specific to the component only. After that, you need to have an analytic report that if not already provided by the OEMs, you need to work on it by yourself. It can be obtained through different kinds of basic or statistical analysis. It is not entirely possible to get all the information about failure mode just via CMMS on the work order, you also need to have some tactics like RCM analysis that will address the failure mode in detail to get the best results out of it. Having all the failure data and processing it with the help of CMMs gives you a great edge in doing predictive maintenance, reduce operational costs and have the right assets in place to your working environment.

Then to make the process smooth and reliable, you need to check the reports on a consistent basis, train your staff and make improvements. Then the configuration of your CMMS is the next step but you need to make sure that it will capture all the validated fields of the failure mode which is specific to the component only. After that, you need to have an analytic report that if not already provided by the OEMs, you need to work on it by yourself. It can be obtained through different kinds of basic or statistical analysis. It is not entirely possible to get all the information about failure mode just via CMMS on the work order, you also need to have some tactics like RCM analysis that will address the failure mode in detail to get the best results out of it. Having all the failure data and processing it with the help of CMMs gives you a great edge in doing predictive maintenance, reduce operational costs and have the right assets in place to your working environment.

Without the failure data, you just have a work order ticket system. That’s why having the correct and useful data increases the efficiency. Most of the organizations don’t involve the reliability engineers in the CMMS, but they are important in identifying the failure analytic. He can help get the exact input out of a system using failure data and failure analysis that is good for getting the potential return on investment. For getting the right fields on the screen, everyone will need training, you need to work together with technicians because they are the ones who can identify the failure mode and the issues with the asset. Then the supervisor and the engineers can help getting the cause codes. It becomes easy when you have the right procedures, perform regular checks and configure the system correctly.

You need to get the inputs from all the possible ways including the knowledge and experience of the technicians and maintenance department, then use CMMS to get the validated fields, work on them and obtain the optimum level of reliability.

References;

- GoMaximo 2016

- IMC 2016

- RCM Blitz by Doug Plucknette

- Reliability Conference 2017

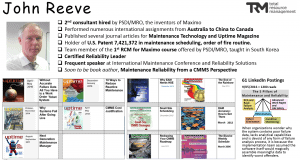

- John Reeve

- Total Resource Management

Rooted In Reliability podcast is a proud member of Reliability.fm network. We encourage you to please rate and review this podcast on iTunes and Stitcher. It ensures the podcast stays relevant and is easy to find by like-minded professionals. It is only with your ratings and reviews that the Rooted In Reliability podcast can continue to grow. Thank you for providing the small but critical support for the Rooted In Reliability podcast!

Reliability engineers are mostly comes from maintenance background and they have little CMMS experience, so they so called asset oriented while the maintenance planners are more CMMS oriented.

So, there must be a group ( I call them Optimization or SMS team) that are mostly having both Reliability and System experience and they are the direct interface to the CMMS port and keep watching the asset management, work management, TA management, inspection & corrosion management, and material management and wirk as facilitators for the RAM analysis, and keep watching the KPI’s for all the systems management (asset, work, TA, I& C, etc) and put recommendations for both teams RAM, and Planners in order to conduct further analysis.