As reliability professionals, we have a lot to do. Risks to identify, failures to analyze. Plans to draft, numbers to crunch. Meetings, writing, research, and leading fill the day.

The list of tasks that you have before you each day is impressive and daunting. So, how do you focus on what actually requires your attention and not just the tasks that get your attention?

Covey suggests scheduling the ‘big rocks’ first, the important projects or tasks, essentially devoting time to what’s important. Allen (Getting Things Done) suggests writing all your tasks down, all of them, and be specific about the next action to move the project forward.

Managing the focus of your own set of projects is difficult and gets more complex when working with a team. As reliability engineers, we work with design and operations engineers and managers. We support decision making at all levels of the organization. We work on more than one team at a time, every day.

An Elegant Chart to Prioritize Tasks

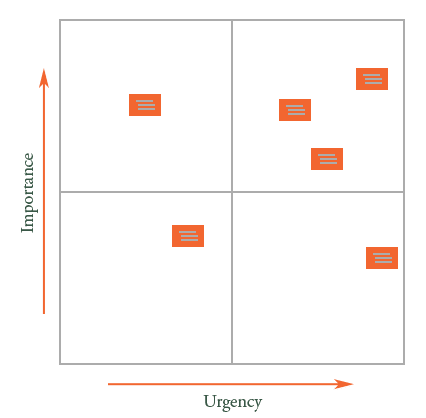

One way to bring into focus the projects and tasks that you and your team need to address is to make the priorities visible. The best way that actually works is to create an urgent versus important matrix. This is also known as the Eisenhower matrix.

The chart has two axes, one for the relative urgency of the project. The other for the relative importance of the project. You can draw this with four quadrants.

Urgency is the when the tasks needs to be accomplished. The deadline or due date in relation to how much time there is between now and then. Items due today are more urgent than items due by the end of the month, for example.

Importance is not related to time, rather it is related to the return on investment or value created. A project that is worth $10 is less important than one worth $100, for example.

Rank order your tasks or projects by their relative importance and urgency. The items that are both urgent and important land in the upper right quadrant, quadrant A. These urgent and important items are thus the ones to focus on and finish before the others.

Projects in the important and not so urgent, quadrant B, and those deemed urgent, yet not as important, quadrant C, rise to be the next to address. You should manage or plan for those important items (B). The urgent and not important tasks (C) are candidates for delegation or limiting. Those in the not urgent nor important (D) are lowest in priority for your attention and should be eliminated.

As timelines change and the perceived value of a project changes so does the arrangement and priorities. As new projects arrive or are accomplished, revise the chart based on the current relative importance and urgency.

The Urgent Task Dilemma

Keep in mind that just because something is urgent does not imply it is important. Yet, as you know, when a deadline looms the perceived importance grows. Separating the two considerations and doing so deliberately allows you to properly assess the priority for a task.

As deadlines approach the urgency goes up. If the project is also important it makes sense to start work while it is still relatively less urgent – meaning you have to choose to work on it even if it’s not due right now. If the project is important and thus worth doing, doing the work well is also worth doing.

Yet, there are 5 items due today, thus urgent. The dilemma is providing enough focus to accomplish urgent tasks, yet maintain progress on the important one.

One way out of this dilemma is to work to avoid the urgent and not important (C) status for a project or task. Finish or delegate the task before it becomes urgent, or decide/negotiate to not work on projects that are not important. In short, a strategy to avoid the less important projects allows you to focus on the more important projects.

A Few Ways to Identify Important Tasks

It is worth repeating, just because a project is urgent does not mean it is important. So, how does one rank projects or tasks based on importance?

One way is your boss clearly identifies which projects are more important than others. While this works, it relies on someone else to judge importance and direct your focus. You and your team can do this just fine on your own.

Another way is to consider the impact the project has when completed. Does the work inform a $250k decision, or does it alter a procedure that improves the quality of every product produced? How you define importance should align with what is deems important in your organization. Profit, functionality, environmentally friendly, etc.

The idea of relative impact or value ranks your projects based on the magnitude or scope of the outcomes.

One exception is the importance of projects involving safety. Like the concept of consequences in an FMEA, projects that work to minimize unwanted consequences avoid the expenses and harm of the undesired events. If the project is successful, there may not be a change in profitability, just a reduced risk that might impact profit, for example.

Finding a Flexible Balance

As urgency and importance change so do your priorities. As new projects arrive or others are completed, the matrix requires review. As you and your team have limited time, choosing where to spend your time assists you in achieving results that are important.

One way to use this tool is to include in a weekly meeting for your team. Include a short chunk of time to discuss the current projects, add new ones, and remove those canceled or accomplished.

Then discuss any changes to importance, then to urgency. Shift the projects (I use Post-it notes on a large sheet of paper) to show the current relative position on the two axes. The align action items or specific tasks across the available resources to make progress on the highest priority items.

Remember this is a planning tool to help you and your team focus on accomplishing what is important along with meeting deadlines. The discussion helps provide a clear set of priorities along with how and why they change.

It takes practice to rank order projects based on importance along with urgency, yet with practice it becomes a quick process.

Leave a Reply