Radar level detectors are becoming a popular technique for tank level detection of liquids.

The radar sends a sub-millionth of a second pulse from an emitter and the return signal is detected at a receiver.

The reflection’s time lapse is measured and electronically converted to a distance from the liquid surface. Installation peculiarities need to be understood and appreciated in order to provide a reliable operating set-up.

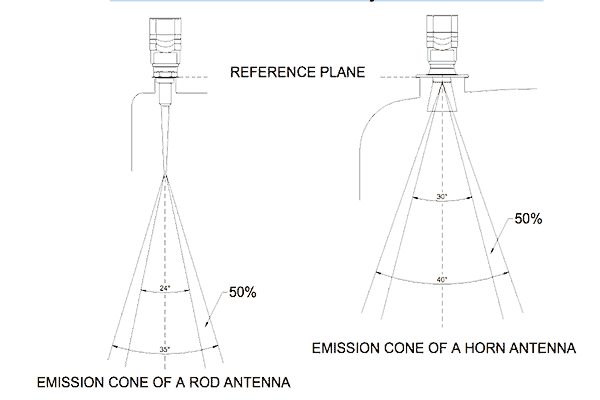

Keyword: antenna, spurious reflection, reference plane, emission cone.

Usually, the radar is mounted in a flanged nozzle or socket welded to the roof.

It can also be mounted in a pressure- balanced standpipe in those tanks with undulating surfaces. The radar can be mounted directly to the roof provided the liquid full height is below the bottom of the antenna.

If the antenna gets below the liquid surface false indication results.

Care must be taken to position the radar to prevent unwanted reflections off tank internal structural beams, wall welds, rivets, etc.

Spurious reflections can be electronically separated from the true level reflection but this introduces programming complications better avoided if possible.

Keep the receiver below the bottom of the nozzle so that it is in clear space. Pulses can bounce off the nozzle walls to the receiver and produce false signals.

Foam on the liquid surface deadens the return pulse.

If located inside vigorously agitated tanks the risk exists that the opening of the antenna cone can get blocked by splashed product.

This is a problem with products that sublime (evaporate then solidify on surfaces) like sulfur or that crystallize.

Check material compatibles and chemical resistance. Especially over many years so that you don’t have reoccurring operating problems.

Mike Sondalini – Maintenance Engineer

Leave a Reply