Module 1 Reliability Concepts & Data

Lesson M01-01

Text: Section 1 page 1

Duration: 18 minutes

- Reliability Analysis Methods

- M01 Reliability Concepts & Data

- 01 Why Reliability & Typical Questions

- 02 Defining Reliability

- 03 Type of Reliability Data & Unique Aspects

- 04 Censored Data

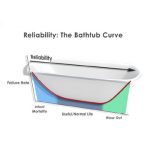

- 05 The Bathtub Curve & Reliability Function

- M02 Probability & Reliability Statistics

- 01 Probability Basics

- 02 Conditional Probability, Independent Events, & Exercise

- 03 Reliability Metrics & Statistics

- 04 Common Distributions & Weibull Distribution

- 05 Conditional Reliability & Exercise

- 06 Review Exercises

- 07 Useful Discrete Distributions & Exercise

- M03 Assessing & Selecting Models for Time-to-Failure Data

- 01 Overview of Distribution Fitting & Reliability

- 02 Probability Plots & Minitab Demonstration

- 03 Constructing Probability Plots

- 04 Distribution Fitting with Right-Censored Data

- 05 Exercises

- 06 Distribution Fitting with Multiple Failure Modes

- 07 Exercise and Module Wrap-up

- M04 Estimation of Reliability Metrics

- 01 Overview of Reliability Estimation & Methods

- 02 Confidence Intervals & Bounds

- 03 Using Minitab to Estimate Reliability Metrics (Demo)

- 04 Exercise

- 05 Reliability Estimation with Censored Data

- 06 Comparing Multiple Groups

- 07 Exercises

- 08 Handling Multiple Failure Modes & Exercise

- 09 Non-Parametric Estimation

- 10 Other Methods for Reliability Prediction

- M05 Introduction to System Reliability

- 01 System Reliability Overview & Basic Series Systems

- 02 Basic Parallel Systems & Short Exercise

- 03 k-out-of-n Parallel Systems & Combination Systems

- 04 Exercises

- 05 Complex Systems

- 06 Reliability Importance, Reliability Allocation, & other Concepts

- M06 Reliability Test Planning

- 01 Reliability Testing Ideas

- 02 Reliability Test Planning & Censoring Schemes

- 03 Reliability Estimation Test Planning

- 04 Exercises

- 05 Reliability Demonstration Test Planning

- 06 Exercise

- 07 Zero Failure Test Plans Special Case & Module Wrap-up

- M07 Analysis of Warranty Data

- 01 Warranty Analysis Overview & Key Concepts

- 02 Data Setup & Calculations

- 03 Minitab Demonstration

- 04 Exercise

- M08 Design for Reliability (DFR)

- 01 Design for Reliability (DFR) Overview

- 02 DFR Process & Methodology Overview

- M09 Introduction to Advanced Topics

- 01 Types of Accelerated Life Testing (ALT)

- 02 Introduction to Quantitative ALT

- 03 Introduction to Repairable System Analysis

- 04 Stress-Strength Analysis

Intense global competition and increasing customer expectationsIntense global competition and increasing customer expectations have increased the pressure on manufacturers to produce high-quality and reliable products. Improving reliability is a key element of the larger overall objective of improving product quality. The survival of any manufacturer today is dependent on its ability to produce reliable products.

Although a primary objective of reliability analysis is to improve product reliability, there are many possible reasons for collecting and analyzing reliability data. Several examples are the following:

- Assessing product reliability in the field

- Predicting product warranty costs

- Assessing the effect of a proposed design change

- Demonstrating product reliability to customers or government agencies

- Improving reliability through the use of laboratory experiments

- Providing risk assessment for safety-critical systems

- Reliability Analysis Methods

- M01 Reliability Concepts & Data

- 01 Why Reliability & Typical Questions

- 02 Defining Reliability

- 03 Type of Reliability Data & Unique Aspects

- 04 Censored Data

- 05 The Bathtub Curve & Reliability Function

- M02 Probability & Reliability Statistics

- 01 Probability Basics

- 02 Conditional Probability, Independent Events, & Exercise

- 03 Reliability Metrics & Statistics

- 04 Common Distributions & Weibull Distribution

- 05 Conditional Reliability & Exercise

- 06 Review Exercises

- 07 Useful Discrete Distributions & Exercise

- M03 Assessing & Selecting Models for Time-to-Failure Data

- 01 Overview of Distribution Fitting & Reliability

- 02 Probability Plots & Minitab Demonstration

- 03 Constructing Probability Plots

- 04 Distribution Fitting with Right-Censored Data

- 05 Exercises

- 06 Distribution Fitting with Multiple Failure Modes

- 07 Exercise and Module Wrap-up

- M04 Estimation of Reliability Metrics

- 01 Overview of Reliability Estimation & Methods

- 02 Confidence Intervals & Bounds

- 03 Using Minitab to Estimate Reliability Metrics (Demo)

- 04 Exercise

- 05 Reliability Estimation with Censored Data

- 06 Comparing Multiple Groups

- 07 Exercises

- 08 Handling Multiple Failure Modes & Exercise

- 09 Non-Parametric Estimation

- 10 Other Methods for Reliability Prediction

- M05 Introduction to System Reliability

- 01 System Reliability Overview & Basic Series Systems

- 02 Basic Parallel Systems & Short Exercise

- 03 k-out-of-n Parallel Systems & Combination Systems

- 04 Exercises

- 05 Complex Systems

- 06 Reliability Importance, Reliability Allocation, & other Concepts

- M06 Reliability Test Planning

- 01 Reliability Testing Ideas

- 02 Reliability Test Planning & Censoring Schemes

- 03 Reliability Estimation Test Planning

- 04 Exercises

- 05 Reliability Demonstration Test Planning

- 06 Exercise

- 07 Zero Failure Test Plans Special Case & Module Wrap-up

- M07 Analysis of Warranty Data

- 01 Warranty Analysis Overview & Key Concepts

- 02 Data Setup & Calculations

- 03 Minitab Demonstration

- 04 Exercise

- M08 Design for Reliability (DFR)

- 01 Design for Reliability (DFR) Overview

- 02 DFR Process & Methodology Overview

- M09 Introduction to Advanced Topics

- 01 Types of Accelerated Life Testing (ALT)

- 02 Introduction to Quantitative ALT

- 03 Introduction to Repairable System Analysis

- 04 Stress-Strength Analysis

Leave a Reply