What you will learn from this article.

- Meanings of ‘loss of function’, ‘failure modes’ and ‘failure patterns’.

- RCM provides a way to select the best maintenance strategy for new plant and equipment.

- PM Optimisation, a shorter version of RCM, is used on existing plant and equipment with sufficient known failure history.

- The RCM process and procedure is introduced.

- How to put RCM outcomes into workplace practice.

Reliability Centered Maintenance (RCM) is one of the great developments in asset management. It is a methodology which studies a piece of plant or equipment in detail, predicts how it can fail, and puts into place the best maintenance strategy to prevent failure, or minimise losses from failure.

Loss of Function and Equipment Failures

A thing fails when it can no longer perform its intended duty. When a pump (or any equipment) cannot do its duty at the designed rate it has a loss of function. If some product is still coming through, people may decide it is sufficient and leave it in service a while longer. Whenever equipment does not satisfy the minimum duty requirement it is considered to have failed. RCM provides a way to detect loss of function before failure.

The aim of Reliability Centered Maintenance is to:

- use equipment and process-knowledgeable people to work out how many ‘reasonably likely’ ways a piece of equipment can lose its function

- use production and process-knowledgeable people to determine the effects and consequences resulting from each loss of function

- decide if the consequences of a failure need to be prevented

- use equipment, process and maintenance-knowledgeable people to come up with effective proactive methods of preventing the failure or agree that no actions will be

performed to prevent the failure - use maintenance and operations-knowledgeable people to turn

the method into situation-practical actions for the operators

and maintainers - buy the necessary equipment to detect the early onset of loss

of function - teach supervisors, leading hands, operators and maintainers the

correct use of the equipment - let people know what to do once loss of failure is noted

Failure Patterns and Failure Modes

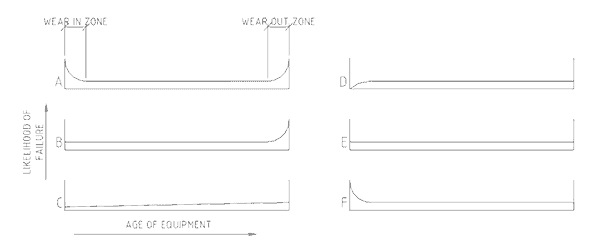

The initiation of a failure has been found to follow one of the six probability patterns shown in Figure No. 1. Evidence from the airline industry indicates that patterns D, E and F represent 89% of failures, with pattern F alone representing 68%. What the shapes highlight is that for most equipment, failure is not age related but can occur at any time.

A piece of equipment can only fail in a limited number of ways. The ways in which it can fail are known as its ‘failure modes’. The RCM process finds the likely failure modes and lets people decide about what to do to detect them early on, so the problem can be corrected before failure. Where the consequences of a failure are unimportant the equipment is left to run to destruction and is then replaced. Where the consequence of failure is important, measures are put into place to prevent failure. This includes condition monitoring, physical inspection, and regular overhauls. If necessary, the equipment is redesigned to remove the failure mode.

The RCM Process and Procedures

RCM uses a team of experienced and knowledgeable people to answers seven questions and come up with a strategy to maintain equipment function. The questions are:

- What are the functions and associated performance standards of the asset in its present operating context?

- In what ways does it fail to fulfill its functions?

- What causes each functional failure?

- What happens when each failure occurs?

- In what way does the failure matter?

- What can be done to predict or prevent each failure?

- What if a suitable proactive task cannot be found?

If the frequency of failure is unknown, research is conducted to find out how often the item is likely to break. Sources of failure data include original equipment manufacturers, equipment life databases, other same equipment users and other similar equipment.

The review process produces proactive tasks that offer effective means of detecting or preventing failure for each asset. The next step is to determine how often these tasks are to be performed so that loss of function is detected early enough to prevent complete failure. The test intervals are selected to be short enough to fit between the point-in-time failure is initiated and the point-in-time the item is considered failed. This requires us to predict the failure.

PM Optimisation

PM Optimisation is a shorter version of RCM used on existing plants with sufficient history on known failure modes. Instead of starting with the first question, PM Optimisation starts with the third question because the failure modes for the equipment are already known from site-specific historical data. It greatly shortens the entire process.

Implementing RCM in the Workplace

After the decisions of how to monitor the failure modes are made, they need to be converted into actions which can be performed at the plant user and maintainer level in the company. This means new procedures, new equipment, new training and new scheduling requirements have to be developed, communicated and practiced.

The transfer from office-logic to plant-logic is where the RCM process often becomes unglued and fails. Plant users and maintainers do not care too much about ‘highbrow ideas’ imposed on them by their managers and outside consultants.

In order for the transfer of RCM outcomes to proceed successfully into the work place every supervisor and leading hand in operations and maintenance must be supportive of the required changes to work practices. Without commitment from these levels in the organisation the implementation success of RCM will be poor.

You get commitment by involving people in the process and its outcomes. The first people (but not the only people) to train in the RCA approach are the supervisors and leading hands. The first people to train in the new technologies to be introduced into the work place are the supervisors and leading hands. And the first people to ask about the best way to get RCM implemented in the work place are the supervisors and leading hands.

Mike Sondalini – Maintenance Engineer

References: John Moubray, RCM II Reliability Centered Maintenance Edition 2, Industrial Press Inc

If you found this interesting, you may like the ebook Process Control Essentials.

Hello, Mike.

I’m glad to read your article about RCM. I got everything about your text, and I would like to read more from you, because this help me to prepare in order to become the best Reliability Engineering in Brazil.

Please, let me hear from you soon.

Best regards,

Thiago Lima.

Whatsapp +5514996133216.

thiago0518@gmail.com

Hello Thiago,

Go to the Lifetime Reliability Solutions website to get all the information, articles and books we’ve released over the years.

All the very best wishes for your future career,]

Mike S.

Hello Thiago,

Go to the Lifetime Reliability Solutions website to get all the information, articles and books we’ve released over the years.

All the very best wishes for your future career,]

Mike S.