As Engineers, Craft and Maintenance people, we have a tendency to be excited by the technological advancements that become available.

This is not a bad thing provided we do not let them become the flavor of the month or take our attention away from what we are here to do. Enable Reliability and Maintenance.

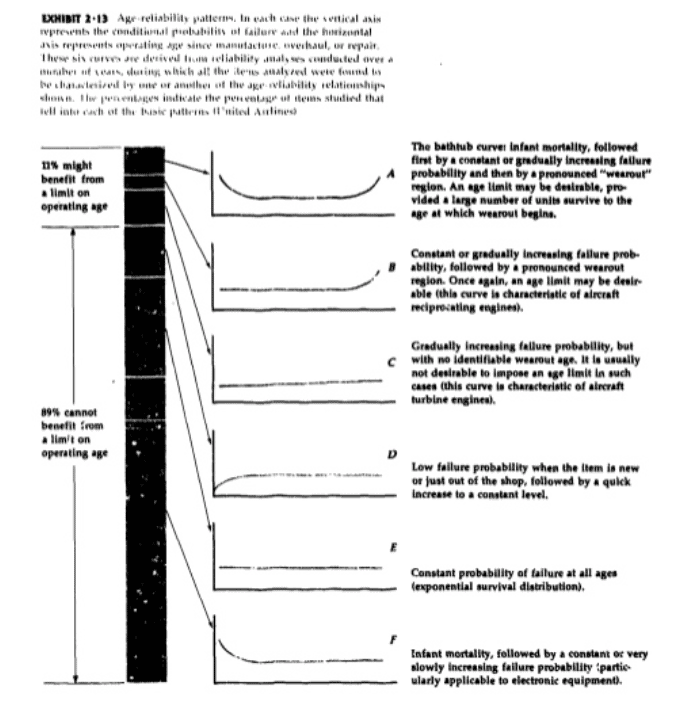

Often we find much information on the advanced technical topics such as Reliability Engineering, Life Cycle Costing, or various CBM technologies. When properly deployed, these techniques allow us to further our success in Reliability and Maintenance.

But what about the foundations that make these interesting techniques successful? [Read more…]