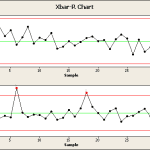

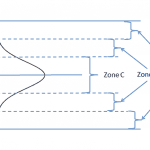

We often jump to the wrong conclusions when non-compliance occurs. Non-compliance occurs when the standards and regulations designed to protect public health and the environment are unmet. Obviously, we must reduce immediate risks. However, these measures often address the symptoms and not the root causes. This leads to further delays or doubling down on the wrong things as we move through mitigation that misses the mark. Using statistical process control in environmental root cause analysis is one way to make sure you’re getting it right!